2021 Doosan 140 tracked excavator Quick hitch Hammer pipe work Air con ...

Want to advertise your business in this space? Simply get in touch with our team. Contact us today.

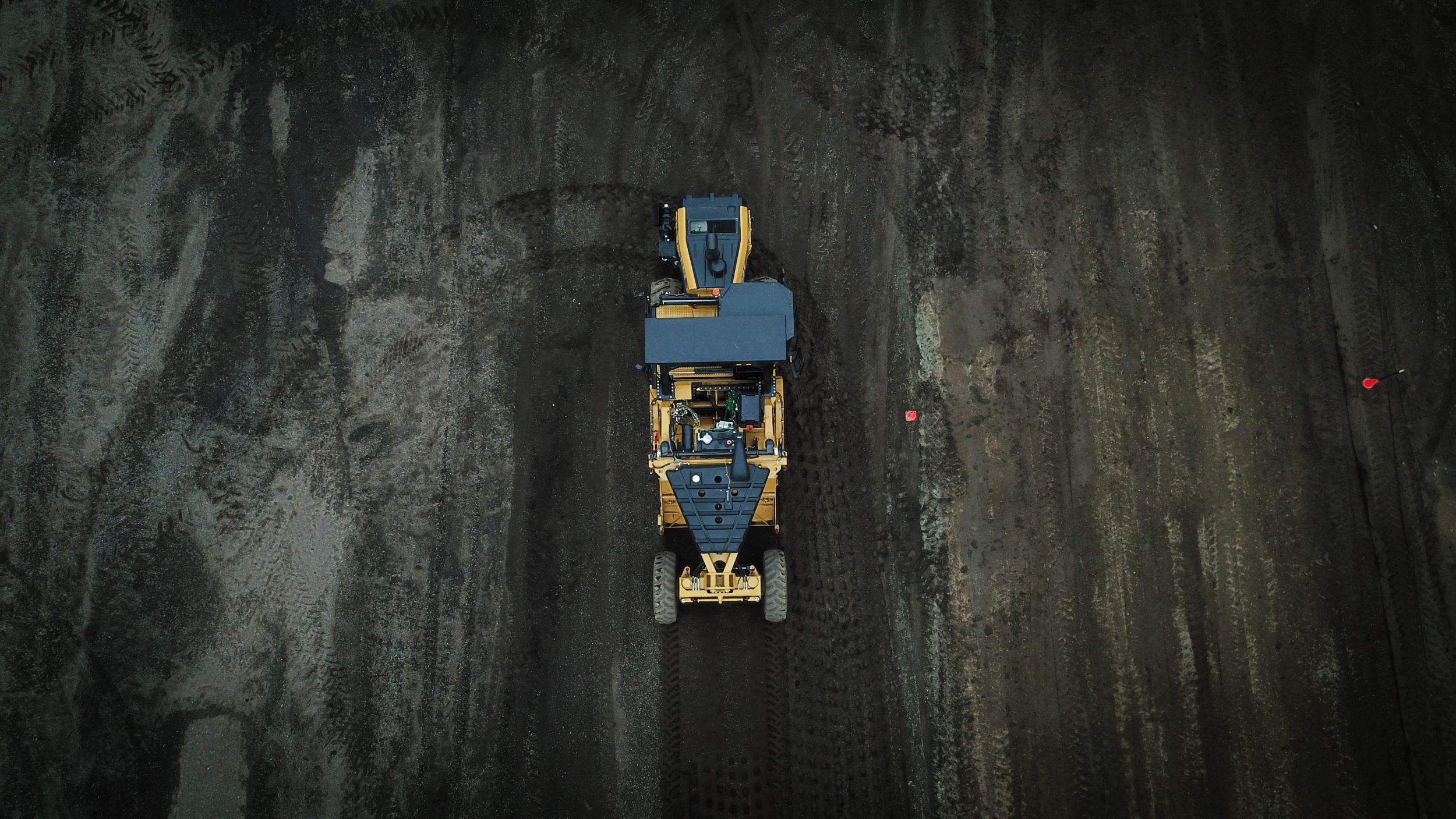

RM400 Road Reclaimer

RM400 Road Reclaimer

POA

Staffordshire

Dealership

0800 028 7778

Favourite

Machinery Details

Category

Manufacturer

VIN Number

N/A

Condition

New

Description

Seller Information

Finance Options

Insurance Options

The versatile Cat® RM400 Reclaimer/Stabilizer delivers excellent material gradation, outstanding maneuverability, and simple operation with superb visibility for excellent overall job site performance. Your toughest road rehabilitation and soil stabilization jobs have met their match.

Maximum Operating Weight

25960 kg

Cutting/Mixing Width

2438 mm

Maximum Cutting/Mixing Depth

508 mm

Product specifications for RM400 Road Reclaimer

Weights

expand / collapse icon

Maximum Operating Weight

25960 kg

Operating Specifications

expand / collapse icon

Cutting/Mixing Width

2438 mm

Maximum Cutting/Mixing Depth

508 mm

Operating Speed

4.8 km/h

Maximum Travel Speed

11 km/h

Rotor Options

Universal, Combination, Spade

Rotor Speed – First (at 2100 Engine rpm)

108 r/min

Rotor Speed – Second (at 2100 Engine rpm)

134 r/min

Rotor Speed – Third (at 2100 Engine rpm)

159 r/min

Engine

expand / collapse icon

Gross Power

310 kW

Engine Model

Cat C9.3B

Dimensions

expand / collapse icon

Length

9.56 m

Width

3 m

Maximum Height

3.5 m

Wheel Base

6.32 m

Ground Clearance

500 mm

Service Refill Capacities

expand / collapse icon

Fuel Tank Capacity

1056 l

Simple to Operate, Easy to Learn

Easily match machine functions with gradation specifications through the 25 cm (10 in) color touch screen displays and push button controls

Precise machine control is delivered through hand-wheel steering

Controls are ergonomically located and grouped by function for quick and easy access

Save time and ensure consistent depth for every cut with automatic features to exit and return to cutting depth

Keyless push-button engine start can add security and convenience using Operator ID codes to recall saved operator preferences and profiles upon login

Boost Performance with Enhanced Visibility

Standard FOPS cab with heating and air conditioning for a comfortable work environment

Sight lines are optimized with the full left-to-right sliding cab

A heated, 180º positioning air-ride suspension seat with fore and aft adjustment increases operator comfort and visibility

Performance and safety can be augmented with standard and optional cameras that are viewed on large, in-cab displays:

Fore and aft visibility is enhanced with standard front and rear mounted cameras

Visibility to each side of the machine can be supplemented with optional side mounted cameras

Obstacle avoidance and gradation results can be viewed with optional cameras mounted above the front and rear mixing chamber doors

Efficient Power with Increased Mobility

Get 19% more power with the Cat® C9.3B engine that provides 310 kW (416 hp) of power and meets regional emission standards

The overall machine length is 44 cm (17 in) shorter to enhance productivity and maneuverability in compact spaces

Maximize traction and mobility with standard, electronically controlled all-wheel drive and four steering modes:Front wheels only, rear wheels only, crab steering, and coordinated steering

Deliver Superior Mix Quality

Advanced electronic controls deliver ideal mix quality by keeping the rotor at the proper depth and the machine at an optimized speed

Manage gradation for a wide variety of materials and applications with three separate rotor speeds that can be selected while in operation

Easily modify material gradation by adjusting the front and rear mixing chamber doors, a simple gauge located on the LCD display keeps the operator informed of door position

Rear rotor chamber door float feature simplifies operation and allows operator to select desired down pressure

Work efficiently on a variety of reclamation and stabilization projects with three rotor options: Universal, Combination and Spade

Optional Spray Systems Deliver Precise Mix Quality

Water and emulsion additive systems ensure mix design specifications are met

Application rate of additives is accurately monitored through a computerized metering system

A wide range of variable flow rates can be optimized for a variety of applications:

Water flow rates from 30-1900 liters per minute (8-500 gallons per minute)

Emulsion flow rates from 30-946 liters per minute (8-250 gallons per minute)

Easily set up the spray system to deliver liquid additives according to specifications: manual or automatic, volume per m2 (yd2) or percent of material density

Easier Service, More Uptime

Ground level access to routine maintenance items simplifies service and improves safety

Auto-reversing cooling fan helps prevent debris build-up extending maintenance intervals for cleaning the cooling package

Rotor drive system utilizes automated bearing lubrication

Self-lubricating rotor chain drive is adjustment-free and eliminates routine maintenance

Hydraulically-actuated rotor drive clutch does not require adjustment

Built-in diagnostics monitor machine systems, alert the operator of performance issues and provide troubleshooting information

RM400 Standard Equipment

Expand all

OPERATING ENVIRONMENT

expand / collapse icon

Adjustable armrests

Air-ride, heated suspension seat

Audio-ready with speakers

Full width sliding cab with heat and air conditioning

Push button start

Illuminated dual-side access ladders

High visibility retractable seat belt

Mini-wheel steering control

Multifunction propel lever

Steering guides

Color touch screen operator interface

POWERTRAIN

expand / collapse icon

Air to Air Aftercooler (ATAAC)

Dual element air cleaner with pre-cleaner

Extended life coolant with protection to -37 degrees C (-35 degrees F)

On-demand fan with auto-reversing function

Four steering modes

All-Wheel Drive

Electronic differential

Oil-bath brake system

Powertrain guard

ELECTRICAL SYSTEM

expand / collapse icon

150 amp alternator

24-volt charging system

Automotive-type fuse system

Remote start/charge receptacle

Two 1365 CCA maintenance-free batteries

ROTOR DRIVE SYSTEM

expand / collapse icon

Maintenance-free drive shafts

Self-lubricating roller and bearings

Shear disk driveline protection

Automatic depth control

Hydraulically-controlled dry clutch

Three rotor speeds

Variable volume mixing chamber

SERVICE AND MAINTENANCE

expand / collapse icon

Grouped filters with ground level access

Cat Product Link™

Remote Flash

Remote access drains

Ports for Scheduled Oil Sampling (S·O·S)

Fluid level sight gauges

Service light receptacles

Toolbox

SAFETY

expand / collapse icon

Back-up alarm (front and rear)

Front and rear facing cameras

Ground level emergency shutdown switches (3)

Horn (front and rear)

ROPS

Platform handrails and guardrails

Mirrors

Working lights (halogen or LED)

RM400 Optional Equipment

Expand all

OPERATING ENVIRONMENT

expand / collapse icon

Additional color touch screen

POWERTRAIN

expand / collapse icon

Bio-friendly hydraulic oil

SPRAY SYSTEMS

expand / collapse icon

Water spray system

Emulsion spray system

Push bar

ROTOR DRIVE SYSTEM

expand / collapse icon

Torque limiter driveline protection

Rotor – Universal 16

Rotor – Universal 18

Rotor – Combination

Material sizing breaker bar

SERVICE AND MAINTENANCE

expand / collapse icon

Integrated air compressor

Pneumatic bit removal tool

Additional toolbox

SAFETY

expand / collapse icon

LED roading lights

Folding LED safety beacon

Folding side view cameras (2)

Front and rear rotor chamber door cameras

Seller Details

Author: finning

Listing Address

Finning - UK Head Office

Cannock

Staffordshire

WS11 8LL

United Kingdom

Cannock

Staffordshire

WS11 8LL

United Kingdom

To learn more about Millbrook Business Finance, click here.

Similar Listings

The versatile Cat® RM400 Reclaimer/Stabilizer delivers excellent material gradation, outstanding maneuverability, and simple operation with superb visibility for excellent overall job site performance. Your toughest road rehabilitation and soil stabilization jobs have met their match.

Maximum Operating Weight

25960 kg

Cutting/Mixing Width

2438 mm

Maximum Cutting/Mixing Depth

508 mm

Product specifications for RM400 Road Reclaimer

Weights

expand / collapse icon

Maximum Operating Weight

25960 kg

Operating Specifications

expand / collapse icon

Cutting/Mixing Width

2438 mm

Maximum Cutting/Mixing Depth

508 mm

Operating Speed

4.8 km/h

Maximum Travel Speed

11 km/h

Rotor Options

Universal, Combination, Spade

Rotor Speed – First (at 2100 Engine rpm)

108 r/min

Rotor Speed – Second (at 2100 Engine rpm)

134 r/min

Rotor Speed – Third (at 2100 Engine rpm)

159 r/min

Engine

expand / collapse icon

Gross Power

310 kW

Engine Model

Cat C9.3B

Dimensions

expand / collapse icon

Length

9.56 m

Width

3 m

Maximum Height

3.5 m

Wheel Base

6.32 m

Ground Clearance

500 mm

Service Refill Capacities

expand / collapse icon

Fuel Tank Capacity

1056 l

Simple to Operate, Easy to Learn

Easily match machine functions with gradation specifications through the 25 cm (10 in) color touch screen displays and push button controls

Precise machine control is delivered through hand-wheel steering

Controls are ergonomically located and grouped by function for quick and easy access

Save time and ensure consistent depth for every cut with automatic features to exit and return to cutting depth

Keyless push-button engine start can add security and convenience using Operator ID codes to recall saved operator preferences and profiles upon login

Boost Performance with Enhanced Visibility

Standard FOPS cab with heating and air conditioning for a comfortable work environment

Sight lines are optimized with the full left-to-right sliding cab

A heated, 180º positioning air-ride suspension seat with fore and aft adjustment increases operator comfort and visibility

Performance and safety can be augmented with standard and optional cameras that are viewed on large, in-cab displays:

Fore and aft visibility is enhanced with standard front and rear mounted cameras

Visibility to each side of the machine can be supplemented with optional side mounted cameras

Obstacle avoidance and gradation results can be viewed with optional cameras mounted above the front and rear mixing chamber doors

Efficient Power with Increased Mobility

Get 19% more power with the Cat® C9.3B engine that provides 310 kW (416 hp) of power and meets regional emission standards

The overall machine length is 44 cm (17 in) shorter to enhance productivity and maneuverability in compact spaces

Maximize traction and mobility with standard, electronically controlled all-wheel drive and four steering modes:Front wheels only, rear wheels only, crab steering, and coordinated steering

Deliver Superior Mix Quality

Advanced electronic controls deliver ideal mix quality by keeping the rotor at the proper depth and the machine at an optimized speed

Manage gradation for a wide variety of materials and applications with three separate rotor speeds that can be selected while in operation

Easily modify material gradation by adjusting the front and rear mixing chamber doors, a simple gauge located on the LCD display keeps the operator informed of door position

Rear rotor chamber door float feature simplifies operation and allows operator to select desired down pressure

Work efficiently on a variety of reclamation and stabilization projects with three rotor options: Universal, Combination and Spade

Optional Spray Systems Deliver Precise Mix Quality

Water and emulsion additive systems ensure mix design specifications are met

Application rate of additives is accurately monitored through a computerized metering system

A wide range of variable flow rates can be optimized for a variety of applications:

Water flow rates from 30-1900 liters per minute (8-500 gallons per minute)

Emulsion flow rates from 30-946 liters per minute (8-250 gallons per minute)

Easily set up the spray system to deliver liquid additives according to specifications: manual or automatic, volume per m2 (yd2) or percent of material density

Easier Service, More Uptime

Ground level access to routine maintenance items simplifies service and improves safety

Auto-reversing cooling fan helps prevent debris build-up extending maintenance intervals for cleaning the cooling package

Rotor drive system utilizes automated bearing lubrication

Self-lubricating rotor chain drive is adjustment-free and eliminates routine maintenance

Hydraulically-actuated rotor drive clutch does not require adjustment

Built-in diagnostics monitor machine systems, alert the operator of performance issues and provide troubleshooting information

RM400 Standard Equipment

Expand all

OPERATING ENVIRONMENT

expand / collapse icon

Adjustable armrests

Air-ride, heated suspension seat

Audio-ready with speakers

Full width sliding cab with heat and air conditioning

Push button start

Illuminated dual-side access ladders

High visibility retractable seat belt

Mini-wheel steering control

Multifunction propel lever

Steering guides

Color touch screen operator interface

POWERTRAIN

expand / collapse icon

Air to Air Aftercooler (ATAAC)

Dual element air cleaner with pre-cleaner

Extended life coolant with protection to -37 degrees C (-35 degrees F)

On-demand fan with auto-reversing function

Four steering modes

All-Wheel Drive

Electronic differential

Oil-bath brake system

Powertrain guard

ELECTRICAL SYSTEM

expand / collapse icon

150 amp alternator

24-volt charging system

Automotive-type fuse system

Remote start/charge receptacle

Two 1365 CCA maintenance-free batteries

ROTOR DRIVE SYSTEM

expand / collapse icon

Maintenance-free drive shafts

Self-lubricating roller and bearings

Shear disk driveline protection

Automatic depth control

Hydraulically-controlled dry clutch

Three rotor speeds

Variable volume mixing chamber

SERVICE AND MAINTENANCE

expand / collapse icon

Grouped filters with ground level access

Cat Product Link™

Remote Flash

Remote access drains

Ports for Scheduled Oil Sampling (S·O·S)

Fluid level sight gauges

Service light receptacles

Toolbox

SAFETY

expand / collapse icon

Back-up alarm (front and rear)

Front and rear facing cameras

Ground level emergency shutdown switches (3)

Horn (front and rear)

ROPS

Platform handrails and guardrails

Mirrors

Working lights (halogen or LED)

RM400 Optional Equipment

Expand all

OPERATING ENVIRONMENT

expand / collapse icon

Additional color touch screen

POWERTRAIN

expand / collapse icon

Bio-friendly hydraulic oil

SPRAY SYSTEMS

expand / collapse icon

Water spray system

Emulsion spray system

Push bar

ROTOR DRIVE SYSTEM

expand / collapse icon

Torque limiter driveline protection

Rotor – Universal 16

Rotor – Universal 18

Rotor – Combination

Material sizing breaker bar

SERVICE AND MAINTENANCE

expand / collapse icon

Integrated air compressor

Pneumatic bit removal tool

Additional toolbox

SAFETY

expand / collapse icon

LED roading lights

Folding LED safety beacon

Folding side view cameras (2)

Front and rear rotor chamber door cameras