THE

COMMERCIAL

TRADER

THE LARGEST MACHINERY MARKETPLACE

Or discover our business directory

At The Commercial Trader, we connect buyers and sellers to create a seamless, user friendly experience. And this doesn’t just stop at products for sale! Discover our selection of professional businesses to find your next commercial partner.

Discover Commercial businesses

Welcome to The Commercial Trader’s Business Directory- your premier destination for discovering and connecting with the best commercial businesses across various industries. Our comprehensive listings directory showcases a vast array of trades and services to help with your professional needs and allows you to search regionally for the best option to meet your requirements.

WHAT WE DO

We’re the largest marketplace for commercial machinery in the UK, connecting buyers and sellers directly for quick and easy access to a wide range of vehicles and equipment. At the Commercial Trader, we’re a trusted platform for specialised machinery and vehicles.

Offering excellent customer service and a reliable platform for businesses to buy and sell equipment. Not only this, standard listings on The Commercial Trader are entirely free for 6 months.

LISTING FEES

We believe in providing flexible and tailored solutions for our customers. That’s why we offer different types of listing fees to suit your unique needs.

FREE

/per listing

- Published for entirely FREE

- Direct contact from buyers

- Features lower in search results

- Easily monitor your listing, and mark your vehicle as sold

- Help with loading multiple listings onto your site.

Please log in/register to create your listings with The Commercial Trader

£2.50

/per week, per listing

- Purchased in 4 week blocks of 28 days

- Featured in the middle of search results

- Direct contact from buyers

- Easily monitor your listing, and mark your vehicle as sold

- Help with loading multiple listings onto your site.

Please log in/register to create your listings with The Commercial Trader

£5.00

/per week, per listing

- Purchased in 4 week blocks of 28 days

- Featured at the top of search results

- Direct contact from buyers

- Easily monitor your listings, and mark your vehicles as sold

- Help with loading multiple listings onto your site.

Please log in/register to create your listings with The Commercial Trader

£2.00

/per week, per listing

- Purchased in 8 week blocks of 56 days

- Featured in the middle of search results

- Direct contact from buyers

- Easily monitor your listing, and mark your vehicle as sold

- Help with loading multiple listings onto your site.

Please log in/register to create your listings with The Commercial Trader

£3.50

/per week, per listing

- Purchased in 8 week blocks of 56 days

- Featured at the top of search results

- Direct contact from buyers

- Easily monitor your listings, and mark your vehicles as sold

- Help with loading multiple listings onto your site.

Please log in/register to create your listings with The Commercial Trader

Have multiple listings? Please get in touch with us as we can help load your products onto the platform, saving you time and hassle.

£9.99

/per month

- Direct contact from potential customers

- Features lower in search results

- Pay annually and get 2 months completely free

Please log in/register to create your listings with The Commercial Trader

£19.99

/per month

- Direct contact from potential customers

- Features in the middle of search results

- Pay annually and get 2 months completely free

Please log in/register to create your listings with The Commercial Trader

£29.99

/per month

- Direct contact from potential customers

- Features at the top of search results

- Pay annually and get 2 months completely free

Please log in/register to create your listings with The Commercial Trader

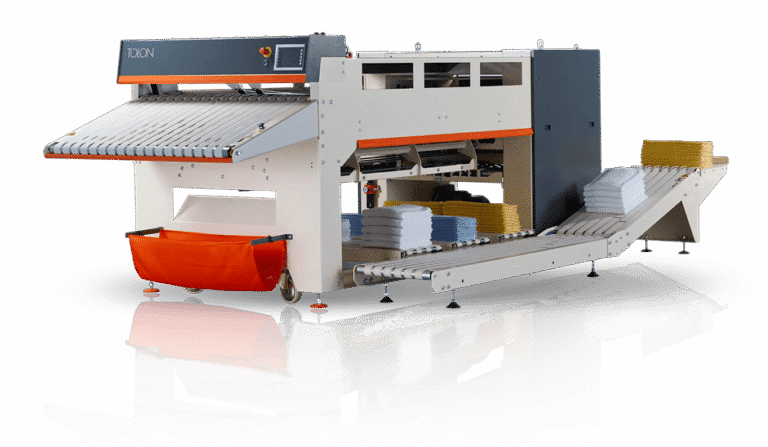

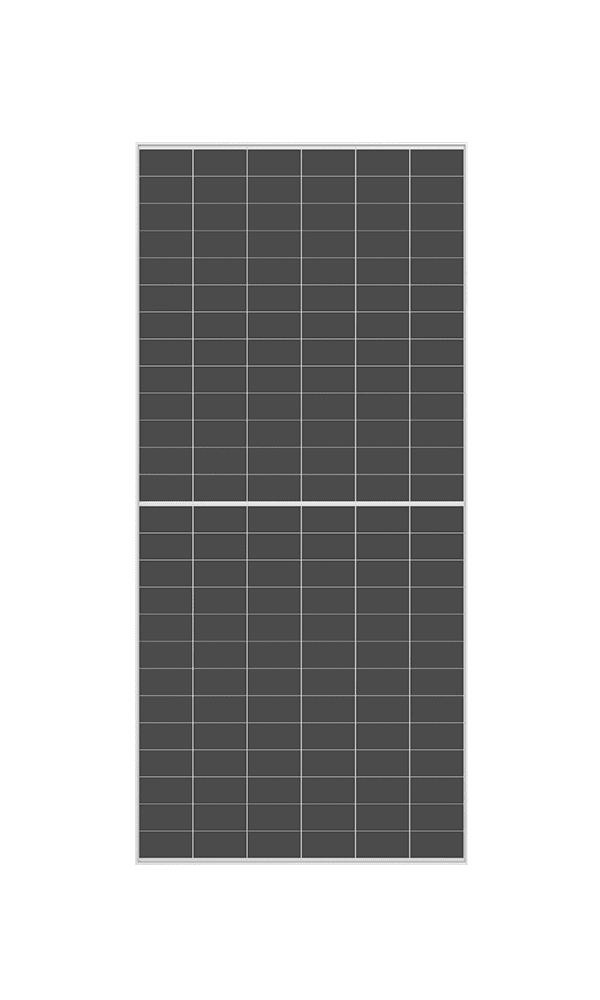

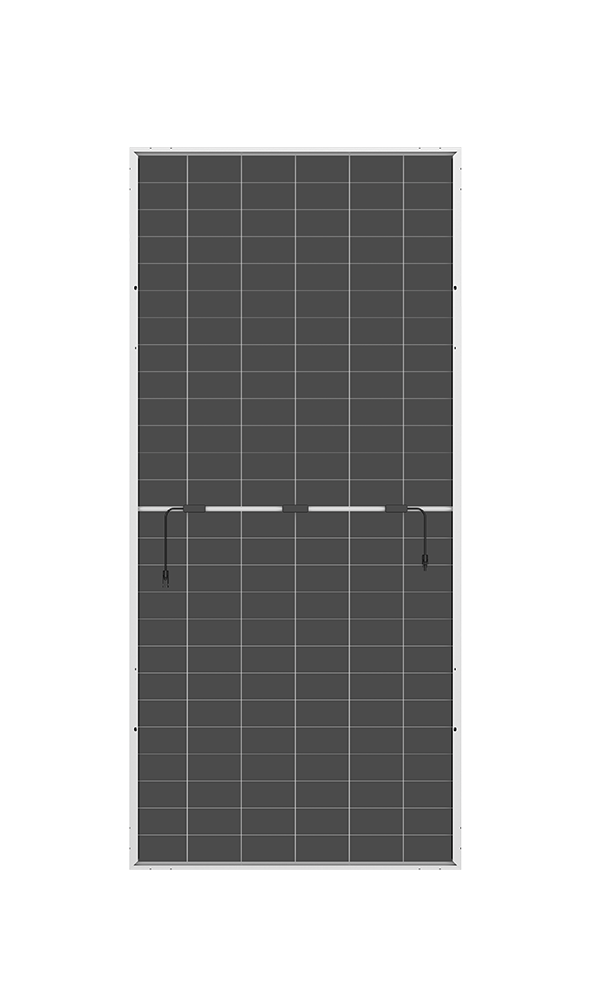

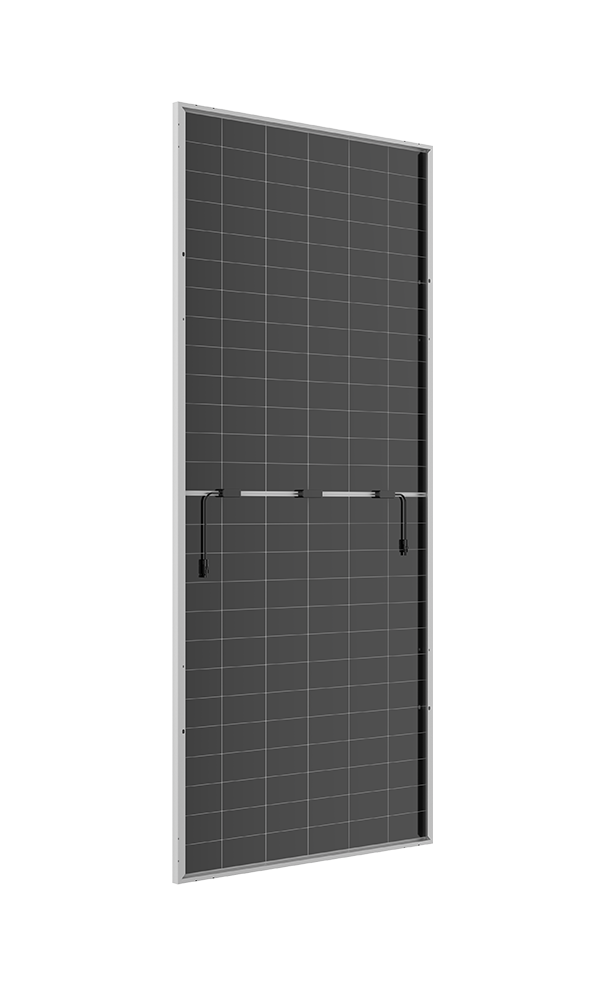

RECENT LISTINGS

- 2004

- 2017

- 2025

- 2025

- 2003

- 2015