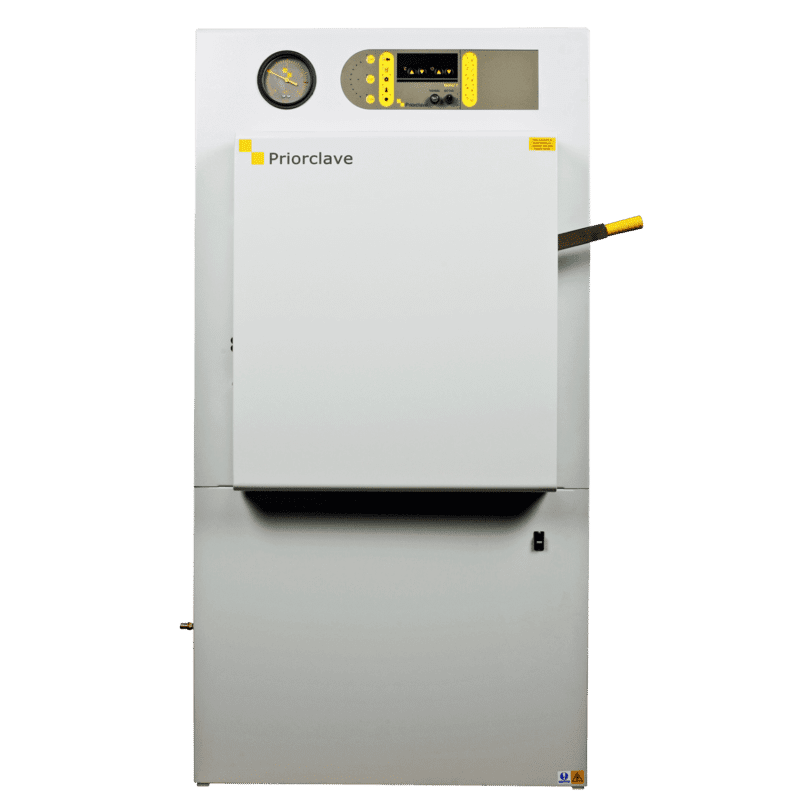

Pass-through autoclaves enable sealed laboratory environments to be maintained, with door interlocks preventing potential for laboratory standards to be compromised. Every double-door autoclave provides a sterile path in and out of sealed laboratories.

At one time, double-door autoclaves were relatively rare. But over recent years we’ve seen â€clean room†high-containment practices adopted in a wide variety of industries, ranging from biomedical research to semiconductor fabrication. While other laboratory autoclave manufacturers are new to this field, Priorclave has been here all along. We offer a variety of flexible pass-through (double-ended) choices with all of the sophisticated containment and safety features you expect from units twice as expensive. Our pass-through autoclaves are used in universities, mobile military facilities, BSL-3 containment suites, and research labs dedicated to West Nile and avian flu, pharmaceuticals, entomology, industrial product development, and more.

GBP £22,750 – 58,750

Product Description

Every Priorclave pass-through autoclave is entirely custom built to your laboratory specifications. Because our steriliser units are all built-to-suit, we can accommodate an almost unlimited number of design considerations specific to your applications and facility: chamber size, steam source, wall thickness, door swing, stainless steel loading shelves and doors, and so on. If you purchase vacuum options, the steriliser is capable of both pre-vacuum and pulsed freesteaming cycles. Autoclave chambers can range from 150 litres to 700 litres in volume, depending on the requirements of your laboratory. Our pass-through autoclaves are front loading, and have round and rectangular chambers.

Our autoclaves come equipped with the Tactrol® 2 Control System, which provides both safety and efficiency features as well as enabling you to automate the sterilisation process. This includes automatic timed freesteaming, which improves air removal and sterilising performance. The Tactrol® control panel can be mounted either inside or outside the containment area (depending on the application), as can any data ports or the hardware printer. The panel can provide visual feedback for where the autoclave is in the sterilisation cycle (vacuum, media warming, cooling, etc.). Pressure interlocks, thermal safety locks, and double-door interlock mechanisms prevent any inadvertent cycle disruptions or breaching of containment integrity. We regularly outfit our BSL-3 (biosafety level 3) pass-through autoclaves with Effluent Retention systems, which include condensate re-sterilisation and 0.05 micron filters in the vent outlet (capable of capturing organisms as small as viruses). These are required by law in some biosafety contexts, but also valuable in non-BSL settings where waste loads are frequently processed. Our double- door autoclaves also feature epoxy coated panels and frame members which are treated with an anti-bacterial agent which is effective against all bacteria and fungi including MRSA.

Models

Model: EH150D-BASE

Model: SH150D-BASE

Model: EH150D-SMART

Model: SH150D-SMART

Model: EH200D-BASE

Model: SH200D-BASE

Model: EH200D-SMART

Model: SH200D-SMART

Model: EH450D-BASE

Model: SH450D-BASE

Model: EH450D-SMART

Model: SH450D-SMART

Model: EH450D-PERFORMANCE

Model: SH450D-PERFORMANCE

Model: EH700D-BASE

Model: SH700D-BASE

Model: EH700D-SMART

Model: SH700D-SMART

Model: EH700D-PERFORMANCE

Model: SH700D-PERFORMANCE

Standard Features

Programmable TACTROL® 3 Control System with simple “one-touch” start

Customizable Freesteaming, Load Cooling, Media Warming, and Delayed Start

PED-certified 316L Stainless Steel Chamber and Door

Full width stainless steel anti-tip Loading Shelves

Biomasterâ„¢ Antimicrobial Surfaces

Air Intake Filter System

Auto-waterfill

Calibration

Cycle Repeat

Air Ballast System

Accelerated Media Cooling

Adaptation for special water supplies.

Additional Options Kit for Health Service Customers

Air Ballasting with built-in air compressor

Condensate Collection Bottle

Customer requested Pressure Vessel Approval

F0 Integration

Factory Acceptance Test

Graphic Recorder Ethernet Port

Heater Protection

Installation – UK Mainland

IQ/OQ/PQ Documentation

Load Sensed Process Timing

Manual Drain

Mechanical Cycle Counter

Operator Identification

Performance Testing

Pneumatic Valves

Recorder – Circular Chart

Recorder – Graphic – Logger

Recorder – Strip Chart

Serial Communications Package

Setting Lock

Steam / Electric Heating

Steam Supply Set

TACTROL Self – Monitoring System

Touch Screen Option

Water Softener

Specifications

150L Double Door Specifications

Working Volume

150 litres

Chamber Size

diameter x depth

500mm dia x 535mm

Chamber Material

burnished 316 stainless steel

Operating Range

up to 138°C, 2.4 bar

Loading Format

Front Loading

Loading Height

860mm

Heater Power

7kW 30A 1 phase or 10.5kW 15A 3 phase

200L Double Door Specifications

Working Volume

200 litres

Chamber Size

500mm dia x 1025mm

Chamber Material

burnished 316 stainless steel

Operating Range

up to 138°C, 2.4 bar

Loading Format

Front Loading

Loading Height

860mm

Heater Power

7kW 30A 1 phase or 10.5kW 15A 3 phase

450L Double Door Specifications

Working Volume

450 litres

Chamber Size

675mm x 900mm x 755mm

Chamber Material

burnished 316 stainless steel

Operating Range

Up to 138°C, 2.4 bar

Loading Format

Front Loading

Loading Height

800mm

Heater Power

32.5kW , 45A 3 phase

700L Double Door Specifications

Working Volume

700 litres

Chamber Size

675mm x 1360mm x 755mm

Chamber Material

burnished 316 stainless steel

Operating Range

Up to 138°C, 2.4 bar

Loading Format

Front Loading

Loading Height

800mm

Heater Power

42kW , 60A 3 phase