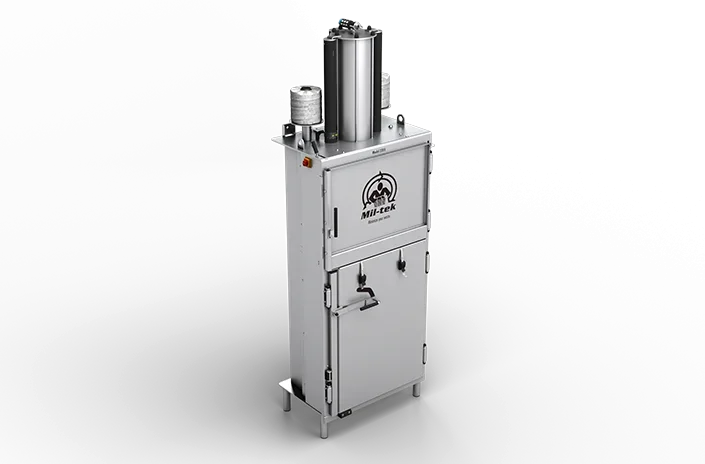

2205s

Stainless Steel Waste Baler

2205s-stainless-steel-grey-baler-on-white-background

The Mil-tek 2205S is a stainless steel baler suitable for cardboard and plastic. The stainless steel design and small floor space footprint makes it suitable for hygienic environments such as industrial kitchens.

Stainless Steel

Small Floor Space Footprint

Enhanced EN16500 Safety Features

Bale and Compact Cardboard & Plastic

Suitable for Kitchens & Clean Environments

Super Fast Pressing Cycle & Bale-out Indicator

pneumatic-air-power-badge

cardboard-badge

plastic-badge

Product Overview

Specifications

Need help?

Download brochure

Add to product comparison

By virtue of being both stainless steel and pneumatic, the 2205S is infinitely more suitable to industrial kitchens that a hydraulic baler. Offering hygienic, contaminant free usage, the 2205S can comfortably handle the heat, moisture and conditions of a busy working kitchen.

The deep vertical chamber allows for large bales, despite a small floor space footprint.

pneumatic-air-power-badge

cardboard-badge

plastic-badge

The Mil-tek 2205S is a stainless steel waste baler suitable for compacting cardboard, plastic and other waste materials. As is it stainless steel, it is ideal for hygienic environments such as industrial kitchens and food production facilities.

The stainless steel allows for 2205S baler to be easily cleaned and maintained, while withstanding the chronic rust and corrosion that affects hydraulic and non stainless steel machines.

The 2205S has a floor space footprint of just 42cm2, making it one of the smallest footprint vertical balers on the market. Despite this, it can create a bale upwards of 120kg. This makes the 2205S ideal for compact, indoor locations where space is at a premium: Kitchens, food preparation areas, storage rooms and waste rooms must all carefully manage space to suit the workflow.

Food producing and food processing businesses that rely on hygienic environments will find the 2205S baler an invaluable addition to their workplace, which excess packaging can be baled at source. One or more strategically placed balers eliminate the need for frequent trips to outside disposal areas.

The Mil-tek 2205S waste baler is fully compliant with the new EN16500 safety standard, making it another addition to Mil-tek’s line of EN compatible machines. Despite have a 24 year, zero accident history, we’ve made further improvements to our machine designs to enhance the operational and safety features.

In addition to enhanced safety features, the 2205S features a faster pressing plate that delivers a full pressing cycle in under 7 seconds. A cycle counter allows users to track the number of cycles the waste press goes through over time, and a bale-out indicator shows when the machine is full.

These features facilitate ongoing maintenance and upkeep of the machine.As with all EN16500-compliant balers, the Mil-tek 2205S waste baler is powered exclusively by compressed air. This means that the 2205S vertical baler is free of electrical and hydraulic components, making it cleaner, safer and more efficient.

Technical specifications

Download tech sheet

Degree of compaction

85%-90%

Carboard Bale

Plastic Bale

Pressing cycle

< 60 kg < 120 kg 7-15 sec. Bale Size Height 960 mm Width 650 mm Depth 450 mm Banding 13mm (#999011) Door Opening Height 475 mm Width 650 mm Depth 415 mm Machine Size Height 2260 mm Width 775 mm Depth 540 mm Noise Noise Level < 70 db Pressure Pressing force at 8 bars 2250 kg Approvals Certifications CE, EN16500, UKCA