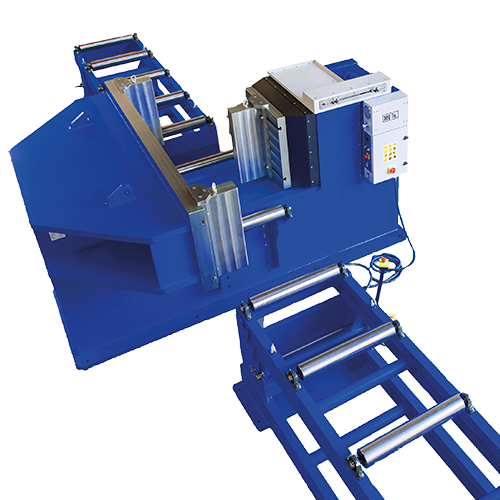

BEAM CAMBERING PRESS • 150 TON • BACK TABLE SIZE OF 500 X 2000 MM • PUSHING TABLE SIZE 500 X 500 MM • THROAT DEPTH 300 MM • GUIDE COLUMNS 50 MM DIAMETER

Product Code: TWPCO-CP-150

The 150T Camber Press delivers 150 tons of pressure and has a piston stroke of 450 mm. Piston stroke is regulated utilising end-stroke switches. The maximum opening between the supporting back table and the main pushing table, opening between tables, is 700 mm. The PPHV-150 has a working speed of 2 mm/s and an approach speed of 9.9 mm/s. After the pressing cycle is complete the cylinder retracts at a rate of 15.4 mm/sec. The overall weight of the Cambering Machine is 6700 Kg.

Our 150T Cambering press is built in the EU with nothing but quality materials and components and features and has a framework constructed from S355JR steel that is electro-welded. The Workshop Press Company UK Cambering Machine has a height-adjustable two-sided roller system and the cylinder is double-acting and the hydraulic cambering press include an anti-turning system.  The main cylinder uses a chrome piston rod and highly accurate limit switches to regulate the cylinder stroke. The hydraulic unit has 2 speeds integrating an automatic high-speed disconnect mechanism when counter-pressure is sensed by the system as well as a pressure regulator and a gauge that indicates tons of pressure.  These Straightening Press machines have an easy to use control panel incorporating a selector for manual or semi-automatic modes and additionally a speed selector for the fast approach and working speed. Forward and backward movements of the cylinder are controlled with low voltage electric pedals.

Our Cambering machines offer a large supporting back table with DIN standard T-Grooves, two heavy-duty support blocks, a main pushing table with four cylindrical lateral guides combined once again with DIN standard T-Grooves and a support block. A combination of the working height and the horizontal design of this cambering machine makes it easy to handle large metal bars, metal profiles, metal beams, large metal tubes, and large metal pipes.

All the machines that WorkshopPress.co.uk offers can be delivered with bespoke options such custom side benches with guide rollers, a larger piston stroke, custom dimensions such as larger vertical daylight, or more advanced controls such as a Siemens NC-control.  We can manufacture any hydraulic pressing machine to suit your specifications.

*** Side Roller Table displayed in the picture is an optional extra. ***

Please contact for prices

PRODUCT ENQUIRY , Technical specifications

Pressure force [kN]: 150

Motor power [kw]: 4

Throat depth [mm]: 300

Working speed [mm/sec]: 2

Approaching speed [mm/sec]: 9.9

Return speed [mm/sec]: 15.4

Pressure max. [bar]: 320

Piston stroke [mm]: 450

Guides diameter [mm]: 50

Opening between tables [mm]: 700

Supporting back table [mm]: 2000 x 5000

Pushing main table [mm]: 500 x 500

Two support blocks back table [mm]: 100 x 100 x 500

One support block main table [mm]: 100 x 100 x 500

Working height [mm]: 900

Total length [mm]: 2520

Total width [mm]: 2000

Total height [mm]: 1570

Weight [kg]: 6700

Features

Large supporting back table

Pushing main table

Support blocks (movable) and T-grooves on both tables

In height adjustable accompanying roller at both sides of the machine

Four cylindrical lateral guides for a perfect alignment of the main table

Adjustable end-stroke switches

Selector for manual / semi-automatic operation

Selector for working with 1 or 2 speeds

Pressure regulator and manometer

Optional accessories

Supporting back table of 4.000 mm

Supporting back table of 6.000 mm

Supporting back table of 8.000 mm

Basic supply rails (as shown in the picture) with height adjustment (available in different lengths)

CNC Siemens

415 mm folding tool-set (PROMECAN clamping system)