Glass chromatography columns for process development or biopharmaceutical manufacture, designed for hygienic operation and easy, efficient packing.

Overview

Glass chromatography columns for process development or biopharmaceutical manufacture, designed for hygienic operation and easy, efficient packing.

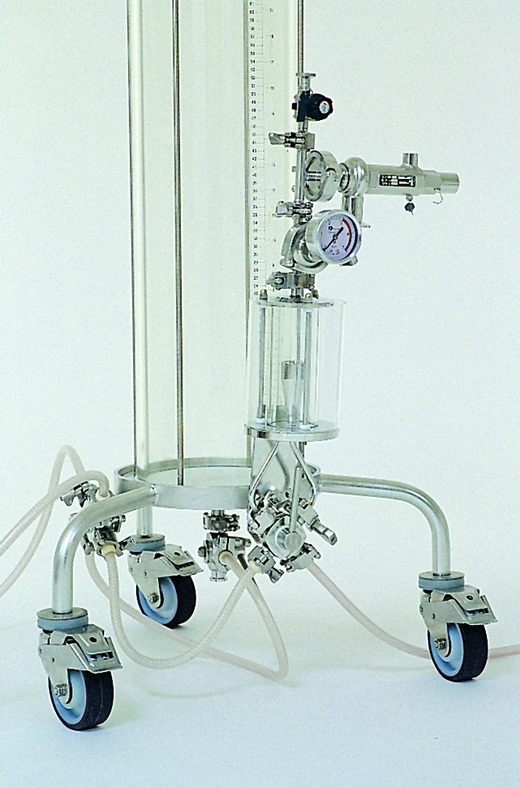

Scalable from 100 mm to 450 mm inner diameter (i.d.) and bed volumes from 2 up to 121 liters. Pressure rating from 2.5 bar to 8 bar, depending on column size.

Glass column tube allows efficient and reproducible packing.

Material Certificates Reports (BPG MCR) available for ordering.

Installation and Operational Qualification Documentation Packages available.

Hygienic design and operation. Microbial attachment and growth is prevented through the use of calibrated precision glass, high-grade electropolished stainless steel and an absence of dead pockets.

Easy, efficient packing and running with the single-screw adapter.

All polymeric materials meet the requirements for USP class VI, described in USP <88> Biological Reactivity Tests, in vivo.

Isolating the column after packing

Sanitary stainless steel valves of the appropriate inner diameter are recommended to prevent contamination of the packed bed. The 2-way or 4-way valves with 6 mm internal diameter are suitable for BPG 100, 140, and 200 columns. The 10 mm internal diameter is suitable for BPG 300 and 450 columns.

For storage purposes, the 25 mm blind flange with a clamp and gasket can be used to seal off the column.

Connecting the column to your system

A clamp and gasket, 6 or 10 mm internal diameter, are required to connect the 25 mm sanitary flanged inlet/outlet to either valves or tubing of the same type. Preflanged tubing in 6 and 10 mm internal diameter is available.

Assembly/disassembly of column

A torque wrench with an appropriate sized socket is required and can be ordered separately.

What else do you need?

Stand kits must be ordered separately.

BPG 100 stand kit has adjustable feet; wheels with brakes are available: product code 18-1031-10. BPG 140 and 200 stands have wheels with brakes as standard: product code 18-1031-20. BPG 300 and 450 are supplied with stainless steel stand with wheels and foot-operated brakes.

Useful spare parts and accessories

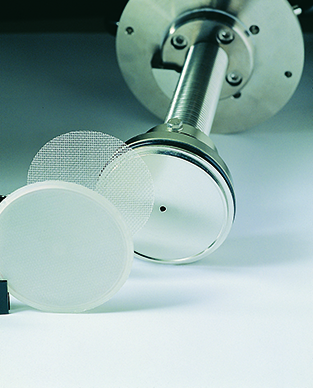

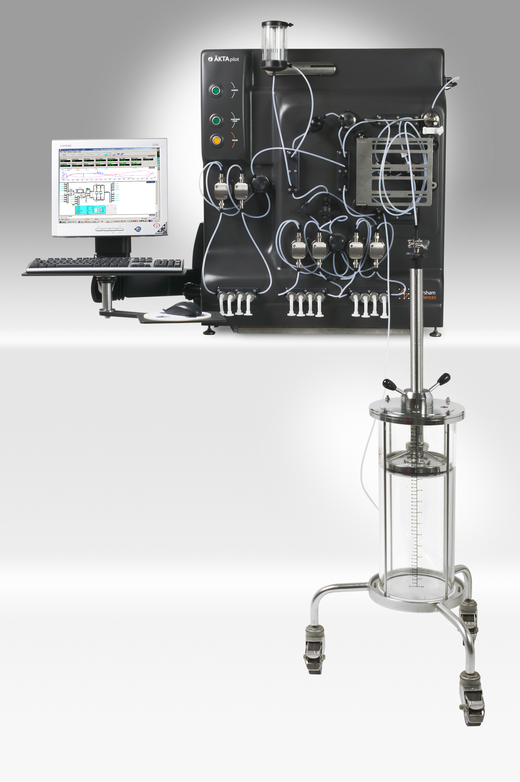

Nets: The column is delivered with 23 µm (polypropylene) nets. For resins with an average particle diameter <70 µm, change to 10 µm (polyamide) or 12 µm (PEEK) in both adapters and end-pieces. For Sepharose Big Beads, use 54 µm nets. O-rings: FEP adapter and sealing O-rings if solvents not compatible with the EPDM O-rings supplied with the column. Gaskets: Use PTFE gaskets if solvent not compatible with EPDM. All nets, support screens and O-rings. In some cases, a spare tube may be advisable. Longer bed heights: Packing extensions are available for all diameters. Air traps: BPG Air Trap Complete includes the air trap, mounting bracket, steel valves, clamps, and gaskets. For air traps for BPG 100, 140, and 200, tubing is included. Top valve: Manually operated valve recommended at the top of the air trap as an air outlet control. Manometers: Manometer kits contain a pressure gauge, T-junction, and necessary clamps and gaskets for sanitary connections. Pressure relief valves: Connected between the pump and column inlet permit flow delivery at a constant pressure throughout the packing procedure. Safety valve: Precalibrated valve that releases pressure if the calibrated value is exceeded. Recommended if the column exceeds its maximum pressure limit and no other pressure sensor is included in the chromatography system. T-junction, clamps, and gaskets have to be ordered separately. Earlier design: For ordering accessories and spare parts to the former design of the BPG 100, 200, and 300 columns, design pressure 3 bar, see Instruction Manual Code No. 18-1030-99. Suitable systems: BPG columns are designed for use with ÄKTAprocess systems and have design pressures of 8 bar (BPG 100), 6 bar (BPG 140 and 200), 4 bar (BPG 300) and 2.5 bar (BPG 450).