A family of convenient process-scale columns with a patented nozzle in the top and bottom of the column that allows packing, unpacking, and cleaning in place. Chromaflow columns are a natural choice when scaling up from BPG columns.

Overview

A family of convenient process-scale columns with a patented nozzle in the top and bottom of the column that allows packing, unpacking, and cleaning in place. Chromaflow columns are a natural choice when scaling up from BPG columns.

For capture or intermediate purification.

Scalable up to 2 m in diameter.

Easy to operate and maintain. Packing knowledge and application support available.

Convenient, pack-in-place nozzle.

Closed system improves safety.

Easy-to-use Chromaflow packing station facilitates packing procedure.

All plastomers in contact with process flow are tested and approved to USP Class VI.

All metallic materials in construction are fully traceable.

Installation and Operational Qualification Documentation Packages and service and maintenance contacts available.

Do it all without even lifting the lid

With Chromaflow columns, packing, operation, unpacking, and cleaning can be performed without removing the lid or adapter – all due to the design of the nozzle in both the top and bottom end-pieces. With the establishment of packing protocols for individual resins, large-scale chromatography is more convenient, scalable and safer for both the operators and the product. Chromaflow columns are intended for GMP production.

How it works

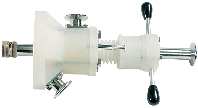

Nozzles sit in both the top and bottom of the column allowing packing in either an upward or downward direction. There are three nozzle positions:

Mid-position, for priming and packing. The bottom nozzle extends part of the way (mid-position) into the column. The top nozzle is fully retracted. Slurry enters the column via the bottom nozzle and excess liquid exits via the top mobile phase outlet. After packing, the slurry lines are isolated from the mobile phase and can be cleaned independently from the rest of the column.

Retracted, for running. The top and bottom nozzles are retracted. Mobile phase enters the column directly into an annulus immediately behind the bed support. The annulus is cut through at an angle to ensure that the linear flow rate is kept constant during distribution of the mobile phase across the bed.

Fully extended into the column for unpacking and cleaning. In this position, both bottom and top nozzles are fully extended into the column, thereby exposing a third passage through which resin leaves the column. Cleaning solution can be pumped through the nozzles and sprayed into the column. In this way, the column is easily and effectively cleaned without exposing the interior or the resin to the outside, or without dismantling the column.

The nozzle also enables isolation of slurry lines from the mobile phase during operation, allowing removal of residual resin and cleaning of the slurry lines independently of the rest of the column.