The Silverson FMX5 is a Laboratory scale version of the Flashmix Powder/Liquid mixer, it operates on the same principle as its larger counterparts and provides an accurate and easy means of predicting the performance of the Flashmix in the laboratory, helping to streamline the scale-up process. The FMX5 has been tested on a wide range of powders, giving comparable results to the production scale Flashmix. These powders include gums (CMC, Guar, Gum Arabic, Pectin, Xanthan), Carbopol, Bentonite and many others across a range of industries.

The FMX5 provides a simple, effective and hygienic means of powder/liquid mixing on a laboratory scale. The unit is suitable for small scale manufacturing and R&D work and is able to process higher viscosity mixes.

Features:

Powerful 1 hp (0.75kW) single phase motor with infinitely variable speed control.

All wetted parts are in grade 316L stainless steel.

Touch pad control panel with digital tachometer, programmable integral timer and amperage display.

Interchangeable rotor/stator arrangements.

1 litre stainless steel hopper as standard; other types are available to assist with flow of more cohesive powders.

Typical batch size up to 10 litres, depending on viscosity.

How It Works

Designed with a Flashmix-style pumping rotor the FMX5 offers a unique method of incorporating powders into liquid, producing an agglomerate-free and homogeneous product at laboratory scale.

Stage 1

The specially modified Silverson Verso Laboratory scale In-Line mixer recirculates liquid from the process vessel through the FMX5 at high velocity.

Stage 2

The powder feed valve is opened, and the high pumping action of the In-Line mixer forces the powder into the liquid stream.

Stage 3

The powder and liquid components are introduced straight into the high shear zone of the mixer, and are instantaneously combined as they are subjected to intense mechanical and hydraulic shear. The resultant mix is passed back to the vessel by the self-pumping Flashmix.

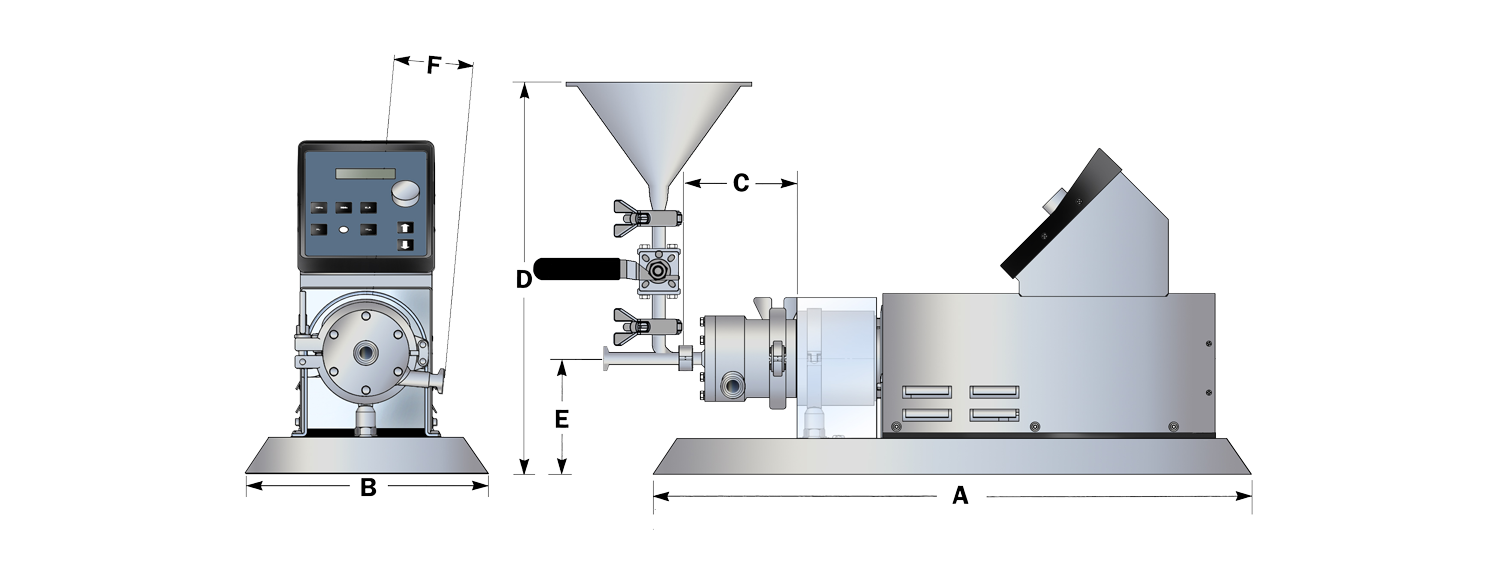

Technical Information

The FMX5 provides simple, effective and hygienic means of incorporating powders into liquids at laboratory scale.

The FMX5 can also be specified as an Ultra-Hygienic model the FMX5 UHS.

Materials of Construction

All product contact parts are in 316L Stainless steel.

Motor Specifications

0.75kW (1hp) 220 volt, single phase (110 volt optional), 50/60 Hz. Nominal maximum speed 9000 rpm.

Inlet and outlet connections

1†Tri-clamp fitting (via adaptor on outlet).

Sealing

Single mechanical shaft seals as standard. UHS specification model available for hygienic applications; this offers single or double mechanical sealing arrangements.

Valves

Ball valve for powder feed.

Cleaning

Designed for Clean-In-Place (CIP) operation.

Hopper

Stainless steel 1 litre hopper standard capacity. Other hopper designs available as optional extras.

Vessel Package

A vessel package including 20 litre vessel, vessel stand, valve and pipework for optimum set-up is available.