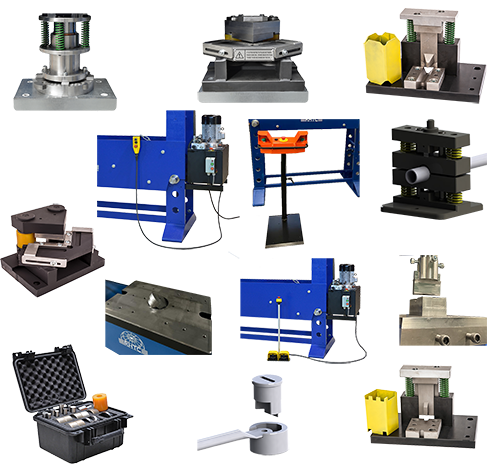

HYDRAULIC PRESS ACCESSORIES & TOOLING SOLUTIONS FOR PRECISION METALWORKING

Product Code: Press-Accessories

Our comprehensive range of hydraulic press accessories is engineered to enhance the versatility and efficiency of your metalworking operations. Designed for compatibility with workshop presses of all sizes, our accessories ensure precision and durability for various pressing applications. From die sets, press brake tools, and work tables to advanced safety features and control options, our selection caters to the needs of the modern manufacturing engineer. Each accessory is meticulously crafted to meet the highest standards of quality and performance, ensuring seamless integration with your hydraulic presses.

Please contact for prices

PRODUCT ENQUIRY , OPTIONAL ACCESSORIES & TOOLS:

V-Block sets for all sizes

Foot pedals for enhanced control

Hand controls for precision operation

Additional safety features including cage guarding and light curtains

System integrations for streamlined processes

Mandrel sets for various pressing tasks

Corner rounding notchers for precise angles

Wedge-shaped punches for intricate cuts

Corner notchers for clean sheet metal work

Hole punches in diverse shapes and sizes

Tube and pipe notching for perfect fits

Drain hole nibbler punch for efficient metalworking

Brake press tooling for versatile bending operations

Custom tools designed to meet specific requirements

Hydraulic Oil Iso 46 and other viscosities

Note: All tools are able to be customised to suit the customer’s requirements.

ADVANCED TECHNICAL SPECIFICATIONS – PRESS ACCESSORIES

Die Sets: Engineered for high-strength applications, featuring precision-ground surfaces for optimal alignment and uniform pressure distribution.

Press Brake Tools: Manufactured from premium, wear-resistant tool steel, offering extended service life and compatibility with a range of press brake models. Includes precision-formed multi-vee dies for versatile bending operations.

Work Tables: Robust construction with adjustable height and orientation settings, facilitating ergonomic positioning for operators and accommodating workpieces of varying sizes.

Trolleys and Carts: Heavy-duty design with industrial-grade casters for smooth transportation of dies and large workpieces, featuring integrated locking mechanisms for stability during loading and unloading.

V-Blocks: Precision-machined from hardened steel for high durability, available in various sizes to support a wide range of pressing applications, ensuring accurate and repeatable results.

Pressing Mandrels: Tailored for complex pressing tasks, these mandrels are fabricated from high-tensile steel, ensuring precise alignment and deformation-free pressing.

Punching Sets: Comprehensive selection of punches and dies, crafted for sharpness and longevity, designed for clean and precise perforations in various metals and alloys.

Tube Notchers: Advanced design for accurate cod-mouthing of tubes, supporting a wide array of tube diameters, especially optimized for 42.2 mm, 48.3 mm, and 42.4 mm, ensuring perfect fit-up for welding operations.

Corner Notcher: High-precision tooling for clean and efficient notching of sheet metal corners, enabling accurate assembly and fabrication of complex structures.

Rod Cutters: Equipped with high-leverage cutting mechanisms for effortless trimming of rods to precise lengths, reducing material waste and improving fabrication efficiency.

Multi-Radius Die Tool: Versatile tooling option for creating rounded corners on sheet metal, available in standard and custom radius sizes, facilitating aesthetic and functional edge finishing.

Safety Features: Comprehensive range of safety enhancements, including light curtains and cage guarding, designed to meet rigorous industry standards and ensure operator safety during press operation.

Control Options: Includes foot pedal, push button, and dual hand button controls, offering intuitive operation and precise control over pressing cycles, enhancing productivity and operational safety.

Customization Options: All tools and accessories can be tailored to meet specific operational requirements, ensuring seamless integration with existing hydraulic press setups and optimizing manufacturing processes.