Why Choose Impact Test Sieve

Strong ability: Especially suitable for the production and grading process of diamond powder and super-hard material industries, and can be used repeatedly with high intensity and frequency.

Wide range: Widely used in scientific research, production and laboratories in geology, metallurgy, abrasives, powders, chemicals, construction cement, medicine, national defense and other departments

Automatic shutdown: Equipped with a variety of clamps, the clamping is flexible and firm, and can automatically shut down

Â

Applicable industry

Chemical industry, Metallurgy and mining industry , Why is impact test sieve more suitable for you?

High degree of adaptability

Can be equipped with a variety of clamps, and the clamping is flexible and firm

Wide range

Used in scientific research, production and laboratories in geology, metallurgy, abrasives, powders, and other departments

High efficiency

Repeated use with high strength and frequency

Save manpower

Can automatically shut down , These industries have chosen impact test sieve

Screening and testing of solid materials in scientific research and production laboratories of geology, metallurgy, abrasives, powders, chemicals, construction, cement, medicine, national defense and other departments

Â

Food industry cases

Pharmaceutical industry cases

Chemical industry case

Metallurgical industry case

Mining industry case

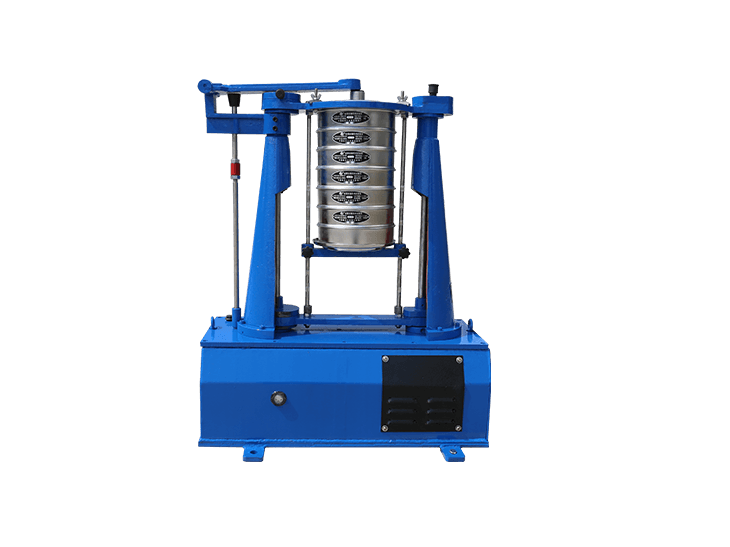

Other industry cases , Technical Parameters

Name Value

Shaking(times/m) 290±5

Impact numbers (times/m) 110±4

Impact height (mm ) 38±6

Reciprocating stroke( mm ) 25

Sieve diameter( mm ) Φ200 Φ75 Φ100

Layer (s ) 5

Motor power( W ) 370

Motor speed( mm ) 1400

Motor voltage( v ) 380

Overall dimension (mm ) 350(L)×450(W)×785(H)

Total weight (kg ) 190

working principle

Adopt Y series three-phase asynchronous motor. The power drive the worm gear and the worm variable speed institutions movement through the coupling transmission, so that the rotating vertical shaft and the camshaft rotate respectively, causing the horizontal circular movement of the sieve and driving the jack to lift and push the slap of the slamming hammer simultaneously. Material produces a circle motion on the screen surface by force, while the striking force of the hammer hit produce jump, tumbling. Finally, the screening process can be completed according to the sieve hole size, to achieve the inspection and classification purpose.