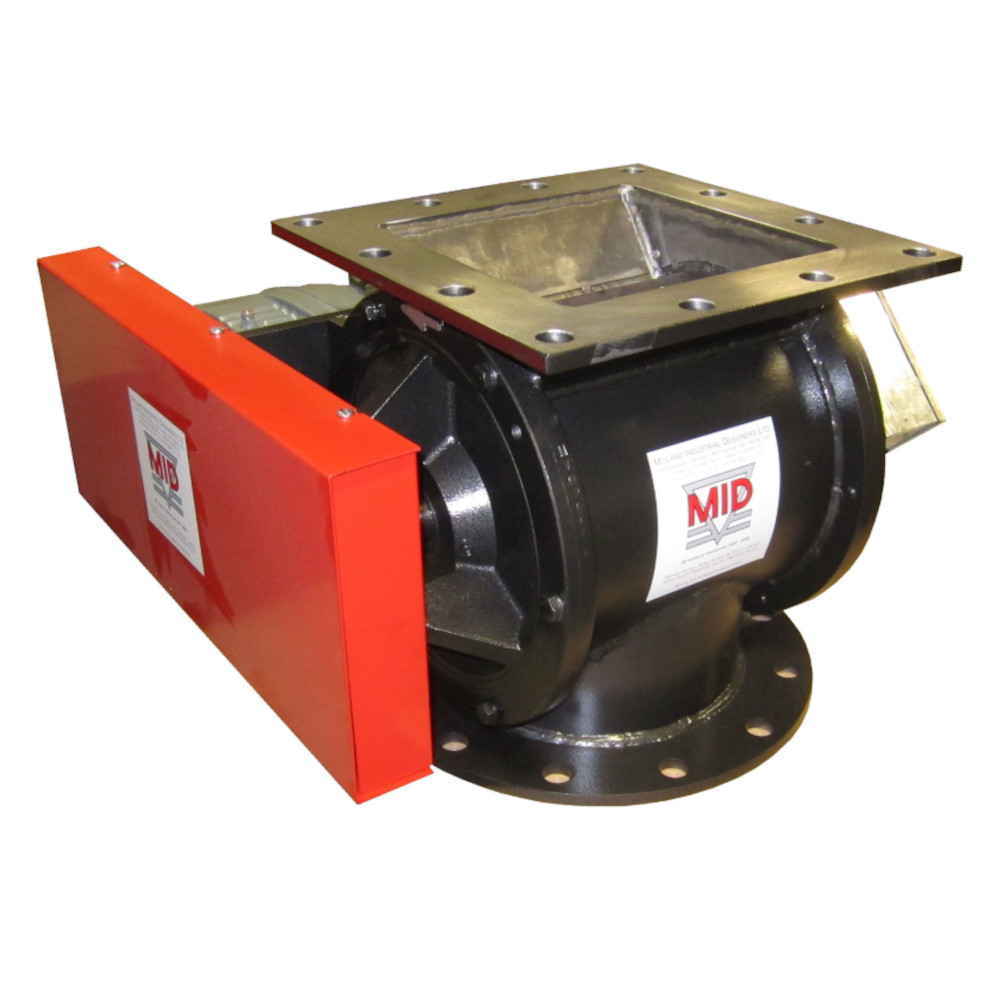

The MVF range is an incredibly flexible way of making a rotary valve exactly fit your application. We can make round, rectangular and square valves in almost any combination.

The MVF range is an incredibly flexible way of making a rotary valve exactly fit your application. We can make round, rectangular and square valves in almost any combination.

We use standard components such as shaft seals and end covers wherever possible to reduce the cost and delivery time of the unit. Freedom of fabrication allows us to use a vast range of materials such as:

Wear plate

Carbon steel

Stainless steel

Exotics (Hastelloy, titanium)

We have made valves that are very large or small, with steam jackets, ceramic linings, pressure shock resistant, and high temperature versions along with various rotors from friction relieved to castellated scrapers.

closed end rotor

stainless steel body

hardened friction relieved tips

mechanical shaft seals

direct drive

For very sticky products we have a range of ways of getting it out of the rotor pockets, from the simplest compressed air jets to active, gear driven synchronised scrapers that mechanically wipe the pocket clean as it rotates. To help even further we can apply non-stick coatings to the valve internals to stop product build-up.

The MVF can also be supplied with ATEX certification for use in hazardous areas.