When composing various powder or granule mixtures or adding micro-ingredients, the right quantities of each substance must be added. Dinnissen has developed various dosing systems for the precise and safe dosing of solids. Read all about our Dosing Slides, Dosing Screws, Dosing Diverters and Feeding Hoppers below, or view the page on our Feeder Valve and Micro Dosing System.

Solids Dosing

Available on request

Markets:

Pet food

Pet food

Process:

It’s important to add each substance at the right time in the right amount, so you can guarantee the quality of each batch. A Dinnissen dosing system ensures extremely accurate dosing, for both large and small quantities of the substance to be added. Which dosing solution fits best depends among other things, on the product to be dosed and the capacity required. We gladly advise you on all possibilities.

Suitable for a few grams to hundreds of kilograms per batch

Very accurate dosing

Designed, tested, and developed in-house

A custom-made dosing system

Adding micro-ingredients such as fats, enzymes, vitamins, and minerals must be done with precision. Adding too much means wastage and adding too few micro-ingredients means lost effectiveness. At Dinnissen we know every substance is different. To accurately dose a substance, not only secure weighing is important, but also the method of dosing. That’s why Dinnissen has developed various dosing systems, each with specific properties and qualities. With a Dosing Slide or Dosing Screw, you effortlessly let through the right amount of substance and with a Dosing Divider, you separate just the right amount of product from the rest.

Tailored to product specifications

Also suitable for micro-ingredients

No product wastage

Always a customized solution

Proven techniques through years of experience

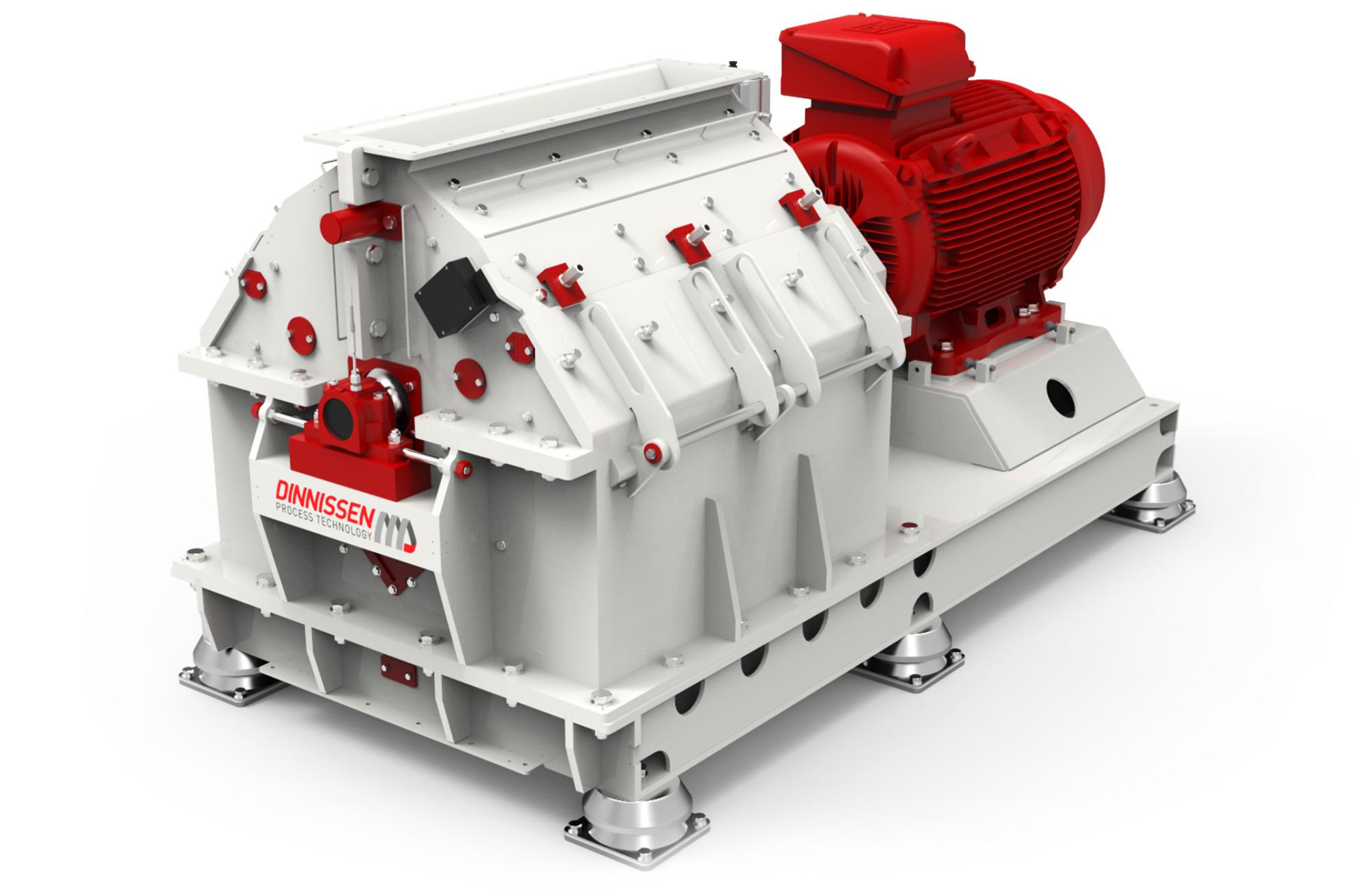

Hamex Hammer Mill 01

Hamex Hammer Mill 03

Key features, options, and models

The key features of all Dinnissen dosing systems are reliability and accuracy. The way a substance is dosed differs per solution. For example, a sticky substance is not processed in the same way as dry powder. And a micro-ingredient requires different processing than bulk goods. All our dosing systems are designed, developed, and tested in-house. So you are always assured of the best possible quality.

Dosing Slide

A Dosing Slide dispenses product using sliding valves. The amount of product passed through, is determined by the frequency with which the slides open and the with of the resulting openings. The Dosing Slide can be set up so that exactly a predetermined amount of product passes through within a certain time frame.

Dosing Screw

A Dosing Screw is – just like the Dosing Slide – extremely suitable for bulk goods. Because of the continuous supply of product, the dosing screw fits well in a continuous process. The dosing screw also works well when adding powders in a vacuum coating process. The screw often has a valve at the end, that opens and closes within a set time. This way products such as powders can be dosed very precisely.

Dosing Distributor

With our Dosing Distributor you don’t move your product from A to B, but from A to B and C. The system can dispense dry bulk goods such as powders, pellets and granulates in two separate directions. This can take place simultaneously, as well as in one direction by (temporarily) closing an output with a slide. You can also close both directions, stopping the entire product flow. The amount of product going in a certain direction can be determined very precisely by not opening the slide completely and thereby narrowing the passage.

Feeding Hopper

The Feeding Hopper is the silo in which the product is (temporarily) stored before it is dosed out. Thanks to years of experience and analysis equipment, Dinnissen specialists can determine exactly how well a product flows out of the Feeding Hopper. We design an installation based on product behavior. Based on experience and testing, we develop the right hopper, reducers, and other components needed to dose your product as best as possible.

How it works

The operation of a dosing system differs for each solution. The Dosing Slide and the Dosing Diverter work with valves that can open and close and thus determine how much product is passed through. The Dosing Screw delivers a certain amount of product per rotation, but at the same time, it can also be equipped with a valve at the end of the screw. The dosing is determined by weight loss (loss-in-weight) or weight gain (gain-in-weight).

In a loss-in-weight system, you measure a raw material that flows out of a weigh hopper per time unit through a dosing system. Beforehand, a weighing module measures the decrease of this raw material from the weigh hopper per time unit and, in combination with a special weighing and dosing control system, calculates the set point. In this way, the weighing and dosing control determines the final dosing capacity (the amount of raw material that flows out of the weighing hopper per time unit) and also ensures that the weighing hopper is refilled in time. This allows the production process to continue uninterrupted, making the system extremely suitable for continuous processes, for example in ovens, extruders, and continuous mixers.

When weighing a batch, the desired weight is set in advance. In a gain-in-weight system, a split is often made between rough dosing and fine dosing. Whereas in the first phase of the dosing process rough dosing takes place, in the last phase the dosing takes place slowly and in small quantities. Dinnissen developed a self-learning control system to optimally regulate this dosing process and to adjust it automatically where necessary. In short, the dosing process can be adjusted to current product conditions to regulate the correct dosing speed and increase dosing accuracy.