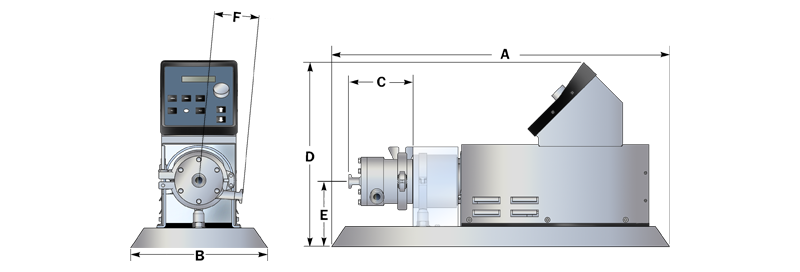

Verso Laboratory In-Line Mixers

The Silverson Verso is a bench top In-Line mixer ideal for laboratory or pilot scale applications. The unit offers excellent reproducibility when scaling up and provides an accurate and easy means of forecasting the performance of larger In-Line mixers under full-scale working conditions.

The Verso is equipped with a digital tachometer, ammeter and programmable timer, invaluable for applications where process validation and reproducibility are required. It is also compatible with the Silverson “DataLogger†program.

Features:

Touch pad control panel

Powerful 0.75 kW (1 hp) motor with infinitely variable speed control

Single or multistage interchangeable workheads available

Self-pumping

Maximum operating pressure 150 psi (10 bar)

0.75†Tri-clamp inlet/outlet connections

Single mechanical shaft seal

All wetted parts are in grade 316L stainless steel

Hygienic construction

Amperage display

In addition to the standard model, the Verso range includes two additional models:

Verso UHS: An Ultra-Hygienic version of the standard model, the Verso UHS is designed for stringent applications in the Pharmaceutical and Biotechnology industries as well as Food, Cosmetics and other clean industries.

Verso-UHS-HV: The Verso-UHS-HV is designed for mixing high viscosity products. It incorporates the same unique and innovative ‘pumping rotor’ design as the production scale UHS-HV In-Line mixers. This substantially increases its self-pumping capacity, allowing it to process products such as gels, creams, sauces and gum solutions on a laboratory scale.

How It Works

Silverson’s Verso Pilot Scale In-Line mixer offers a great many advantages to the processor – speed, versatility, self-pumping, aeration-free, guaranteed efficiency. At the heart of every mixer is Silverson’s high performance rotor/stator workhead.

Stage 1

The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials into the rotor/stator assembly.

Stage 2

Centrifugal force then drives the materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

Stage 3

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator, then through the machine outlet and along the pipework. At the same time, fresh materials are continually drawn into the workhead, maintaining the mixing and pumping cycle.Technical Information

Download Printable Version (PDF)

Capacity

Self-pumping throughputs of up to 2,400 litres per hour.

No Bypassing

Product cannot bypass the precision rotor/stator workhead.

Interchangeable Workheads

Single and multistage rotor/stator configurations as standard.

Materials of Construction

Product contact parts in 316L stainless steel.

Motor Specification

750W (1hp) 220 volt, single phase (110 volt optional), 50/60 Hz. Nominal maximum speed 9000 rpm.

Speed Control

Infinitely variable electronic speed control with integral on/off switch.

Inlet and Outlet Connections

3/4†Tri-Clamp connections. Self-draining tangential outlet.