The AP400 is a wheel-type asphalt paver that provides easy transport, application versatility, and a wide paving range, making it the perfect match for urban streets, parking lots, rural roads and many other small to intermediate-type applications.

Paving Range with SE47 VT

2.4 m – 6.0 m (7′ 10″ – 19′ 8″)

Engine Model (1)

Cat® C3.6 (U.S. Tier 4 Final, EU Stage V)

Engine Power (1)

90 kW

Product specifications for AP400 Wheel Asphalt Pavers

The AP400 is a wheel-type asphalt paver that provides easy transport, application versatility, and a wide paving range, making it the perfect match for urban streets, parking lots, rural roads and many other small to intermediate-type applications.

Dimensions

expand / collapse icon

Paving Range with SE47 VT

2.4 m – 6.0 m (7′ 10″ – 19′ 8″)

Truck Entry Height

544 mm

Operating Length

5.9 m

Operating Width

3.3 m

Overall Height

3.9 m

Transport Length

5.7 m

Transport Width

2.55 m

Transport Height

2.9 m

Engine

expand / collapse icon

Engine Model (1)

Cat® C3.6 (U.S. Tier 4 Final, EU Stage V)

Engine Power (1)

90 kW

Engine Model (2)

Cat® C3.6 (UN ECE R96 Stage IIIA, equivalent to U.S. EPA Tier 3 and EU Stage IIIA)

Engine Power (2)

90 kW

Operating Specifications

expand / collapse icon

Maximum Travel Speed

16 km/h

Maximum Paving Speed – With Tamper Bar Screed

25 m/min

Maximum Throughput Capacity

774 tonnes/hr

Weights

expand / collapse icon

Operating weight with SE47 VT

14581 kg

Shipping Weight – Paver Only

11256 kg

Service Refill Capacities

expand / collapse icon

Fuel Tank

200 l

DEF Tank

19 l

Cooling System – Total

24 l

Hydraulic Oil Tank

121 l

Washdown Spray Tank

32 l

Compact Size, Big Opportunities

The compact size and small footprint simplify maneuverability in tight spaces for efficient work in urban-type applictions

Tight 90º turning capability enables the paver to rotate and cover tracks on a return paving pass

Standard paving range utilizing the SE47 VT screed is 2.4 m – 4.7 m (7′ 10″ – 15′ 4″) with a maximum width of 6.0 m (19′ 8″)

Paving depths up to 300 mm (12″) supports aggregate paving applications

Transport Made Easy

Machine weight of approximately 14.3 mt (31,539 lb) paver and screed combination enables easy transport on a variety of trailer types

Length of less than 5.7 m (18′ 7″) and width of 2.55 m (8′ 4″) accommodates machine transport without special permits. When equipped with 225 mm (9′) extensions, transport width is 3 m (10′) and paving width extends to 5.1 m (16′)

The front-loading angle of 19º and high front bumper clearance reduces the need for additional blocking when loading onto various trailer designs

Raising or retracting the canopy is fast and easy with both electric or manual options available

Front, middle, and rear tie-down locations make securing the paver efficient for quick travel to the next job site

Exceptional Mobility

Wheel undercarriage provides exceptional mobility and fast travel speeds for unmatched maneuverability around the job site

Excellent traction is delivered through the 15.5 R25 radial tires

Front-wheel assist option provides power to the rear set of bogie wheels for excellent performance in tough conditions

High, front ground clearance of 203 mm (8″) helps avoid storm drains, curbs, and other obstacles

Smooth Material Flow

Single amplitude tamper system with variable frequency screed plate vibration delivers excellent material flow and tight mat textures

Low truck entry height and short front apron enhances material flow while simplifying clean-out

Feeder system design with 355 mm (14″) diameter augers provides consistent material flow across the screed for efficient flow at both narrow and wide paving widths

Narrow auger chamber keeps material moving and helps eliminate stagnate patches

Independent control of each material feed sensor, simply turn off the sensor for manual proportional feed control

More Comfort

Optional ventilation system draws fumes from the auger chamber and redirects them away from the operator for a more comfortable working environment

Single sliding console enables operation from either side of the machine

Dual independent seats swing out 40 degrees beyond the platform for good visibility to curbs and obstacles

Optimized height and integrated exhaust provide unobstructed visibility around the machine

Optional screed and paver mounted umbrellas offer protection from direct sun

Heated seat option delivers comfort in cool weather conditions

High visibility 76 mm (3″) seat belt helps with crew safety compliance

Easy Viewing Displays

High-definition, touchscreen displays with adjustable brightness control for all types of lighting conditions, including direct sunlight

New touch screen operating display with simplified menu structures, intuitive graphics, and short-cut keys help simplify machine adjustments

Single-touch functions from the main screen include screed heat, wash-down system, vibratory activation, ventilation system, and the accessory panel

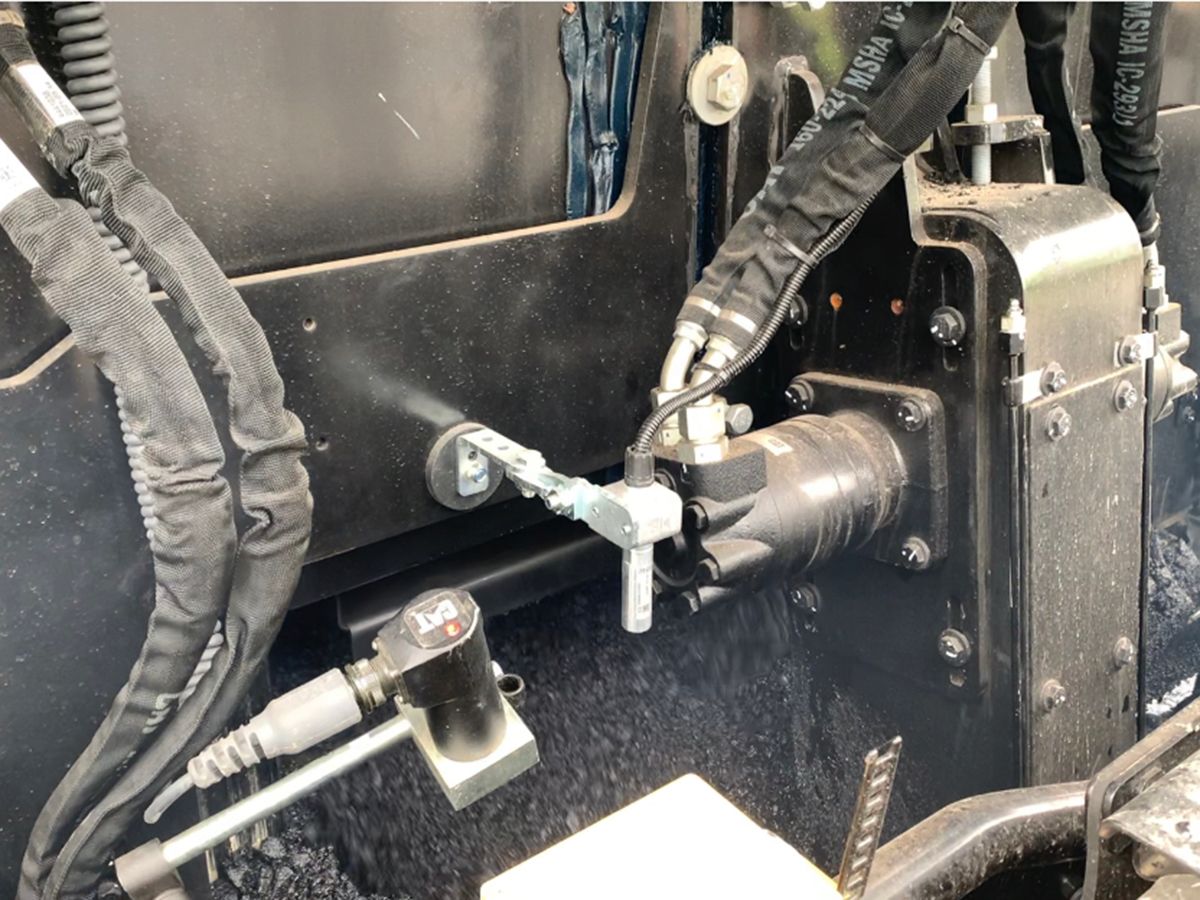

Cat® Grade Control or Basic Grade Control options available

Operating displays can be tailored to specific language requirements with multiple options available

Wash-down system includes level indication

Low Owning and Operating Costs

Durable Cat C3.6 engine provides 90 kW (120 hp) of power with variations that meet U.S. EPA Tier 4 Final and EU Stage V emission standards. The Cat 3.6 engine also meets Brazil MAR-1 and UN ECE R96 Stage IIIA emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

Single source supplier of Cat engines and machine parts helps maximize uptime

Exclusive Eco-mode and Automatic Engine Speed Control reduce fuel consumption and lowers sound levels for better job site communication

Conveyor bed plates and chain guards are designed to minimize labor requirements and lower replacement costs

Maintenance-free high torque motors for the auger and conveyor drive systems reduce service requirements

Product Link™ Elite

Make timely, fact-based decisions to maximize efficiency, improve productivity, and lower owning and operating costs

Easily track location, machine hours, fuel usage, and idle time in real time

Diagnostic codes are made available through online web applications

Remote flash for easy software updates

Scheduled maintenance and Scheduled Oil Sampling notifications

Remote disable deactivates the engine for enhanced security

Service and Repair Kits

Paver and screed service and repair kits include all the parts necessary to complete specific repairs

Cat genuine parts are manufactured to precise specifications and designed for optimal performane and maximum uptime

Repair kits are identified by a single part number to make ordering easy

Select kits are available to be packaged as a kit by the dealer for over the counter purchases or through the dealer service shop

AP400 Standard Equipment

Expand all

Operating Environment

expand / collapse icon

Single sliding console

Steering guide

Technology

expand / collapse icon

Product Link™ Elite 643 (cellular)

Powertrain

expand / collapse icon

Ballast – front weights

Cat® C3.6, four-cylinder

Cooling fan, variable speed

Radial drive Tires

Electrical System

expand / collapse icon

1400 CCA battery, maintenance-free

150-amp alternator

12-volt charging system

Automotive-type fuse system

Auto-reset breaker for material sensors

Cat® Electronic Technician (Cat ET)

Material Delivery

expand / collapse icon

Auger extensions, 0.15 m (6″)

Material feed sensors, contact

Push-roller, adjustable

Tamper Bar System

Service and Maintenance

expand / collapse icon

Hydraulic oil, Cat HYDO™ Advanced

Remote access drains

Remote flash

Service repair kits

Sampling ports for Scheduled Oil Sampling

Sight Gauges, engine coolant, hydraulic oil

Safety

expand / collapse icon

Alarm, back-up

Horn, warning (front & rear)

Lights, LED Working

Mirror package

AP400 Optional Equipment

Expand all

Operating Environment

expand / collapse icon

Canopy, hydraulic lift manual

Canopy, hydraulic lift power

Deceleration pedal

Heated seat

Umbrella

Ventilation system

Side shields

Windshield

Technology

expand / collapse icon

Cat® Grade Control

Basic Grade Control

Product Link™ Elite 683 Cellular/Satellite

Powertrain

expand / collapse icon

Front-wheel assist

Material Delivery

expand / collapse icon

Auger extensions, 0.46 m (1.5′)

Mainframe extensions, power

Mainframe extensions, manual

Material feed sensors, sonic

Wash-down pump and reel

Safety

expand / collapse icon

Lights, LED Roading

Warning beacon, LED

Lights, LED Roading

Warning beacon, LED