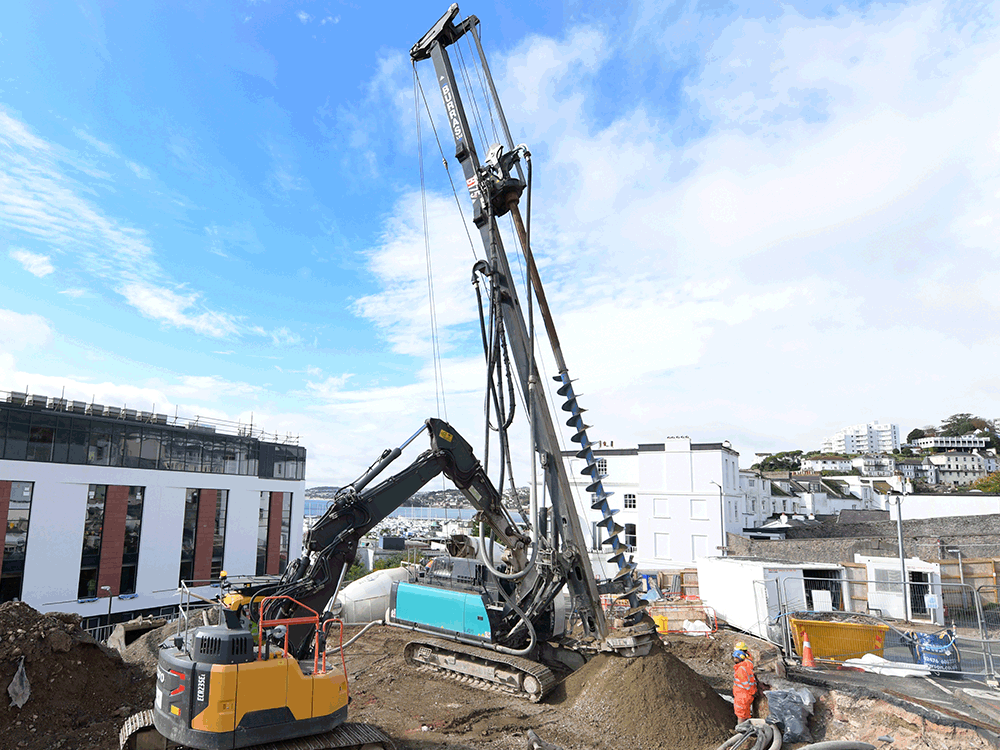

The Casagrande B125 XP-2 CFA is a multifunctional hydraulic piling rig for foundation construction utilising modern power systems and PLC machine controls , 186 kW

Engine Power

160 KNm

Torque

205 kN

Extraction Force

32 RPM

Rotary Head Speed

900 MM

CFA Diameter

23.6 M

CFA Depth

56 kN

Crowd Force

41 T

Operating Weight , ABOUT

TECHNICAL

OPTIONS

The Casagrande B160 XP-2 in CFA Configuration is a machine dedicated to giving the specialist contractor equipment to perform large diameter rotary and CFA piling. It is the result of research and innovation based on over 50 years of experience and success of the company in the field of foundations and geotechnical engineering.

Designed to work on the most difficult sites and has excellent technical characteristics: 160 kN high speed winch for fast work, the H16 rotary head has a maximum torque output of 160 kNm and speed up to 32 rpm, it is ideal for drilling large and small diameter boreholes.

The SPM (Smart Power Management) allows intelligent engine power management in order to improve the performance and productivity of machinery. The XP technology monitors the instantaneous power and hydraulic flows and allocates the full available power according to the requirements of the task. The result is an increase in the machine effi ciency.

“Keep the operator happy in a comfortable working environment” is our formula for added productivity. The B160 XP-2 is designed to satisfy the severe European Union standards on safety and is manufactured to comply with the ISO 9001 requirements on quality.

PERFORMANCE AND PRODUCTIVITY

The Smart Power Management (SPM) is an intelligent engine power management system that improves performances and productivity of the machinery. The SPM system monitors the momentary power flows and immediately allocates the available power to the different jobs, so the operation function has always the maximum power available.

SAFETY & TECHNOLOGY

The B160 XP-2 has a very low sound emission level as a result of the of sound-absorbing materials and oil heat exchangers, designed for reducing the overall noise level. The layout of the machine and the wide openings of the canopy offer comfortable and easy access for inspection and maintenance. The machine conforms to the last international standards to guarantee the maximum safety of the operations.

SAFETY & TECHNOLOGY

The B160 XP-2 has a very low sound emission level as a result of the of sound-absorbing materials and oil heat exchangers, designed for reducing the overall noise level. The layout of the machine and the wide openings of the canopy offer comfortable and easy access for inspection and maintenance. The machine conforms to the last international standards to guarantee the maximum safety of the operations.

FULL LOAD SENSING TECHNOLOGY

The XP-2 hydraulic power system uses the Full Load Sensing (FLS) technology. Unlike the common hydraulic

managing systems, the FLS pressurizes only the required amount of oil requested by users thanks to the back-action between pumps and distributors. It allows to manage the power demands and reduces dissipations, achieving up to the 25% of fuel saving (calculated on the basis of a theoretical working cycle).

FLEXIBILITY

The XP-2 control system offers the following advantages for the operator and the supervision of the work: monitoring of all working function, diagnostic of the working systems to ensure the constant monitoring of the status of sensors and components, easy conversion in any drilling arrangement, friendly customization of working functions e.g. mappings of torque and speed for EP rotary head, remote rigs assistance, diagnostic, monitoring of working parameters.