The Cat® D8 dozer (formerly D8T) increases your dozing productivity up to 18% without using more fuel. This means you can move more material in less time, at a lower cost per ton, so you get a faster payback on your equipment investment. The D8 bulldozer offers unprecedented ease of operation as well. A Caterpillar designed, smooth shifting, fully automatic 4-speed transmission makes it easy for operators of all experience levels to achieve optimal productivity and efficiency without having to manage gear shifts. Factory integrated Grade technology options help you get quality work done even faster, from first pass to finish grade, while relying less on operator input.

Engine Model

Cat C15

Power – Net

264 kW

Net Power – ISO 9249/SAE J1349

264 kW

Product specifications for D8 Medium Dozers

Engine

expand / collapse icon

Engine Model

Cat C15

Power – Net

264 kW

Net Power – ISO 9249/SAE J1349

264 kW

Net Power – ISO 9249 (DIN)

359 mhp

Emissions

U.S. EPA Tier 4 Final/EU Stage V/Korea Stage V

Note (1)

Net power at 1,900 rpm. Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator. Advertised power is tested per the specified standard in effect at the time of manufacture.

Note (2)

Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) ** or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. ** Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer).

Note (3)

Machine Build Number 21B

Weights

expand / collapse icon

Operating Weight

39750 kg

Transmission

expand / collapse icon

Power Train

Fully Automatic 4-Speed Powershift

Service Refill Capacities

expand / collapse icon

Fuel Tank

627 l

DEF Tank

24 l

Standard SU

expand / collapse icon

Operating Weight

40233 kg

Ground Pressure

91 kPa

Width of Standard Shoe

610 mm

Blade

Semi-Universal (SU)

Blade Capacity

10 m³

LGP

expand / collapse icon

Operating Weight

38513 kg

Ground Pressure

55.3 kPa

Width of Standard Shoe

965 mm

Blade

Semi-Universal (SU)

Blade Capacity

9.9 m³

Waste Handler

expand / collapse icon

Operating Weight

40010 kg

Ground Pressure

91 kPa

Width of Standard Shoe

610 mm

Blade

Semi-Universal (SU) Landfill

Blade Capacity

28 m³

LGP Waste Handler

expand / collapse icon

Operating Weight

42489 kg

Ground Pressure

61 kPa

Width of Standard Shoe

965 mm

Blade

Semi-Universal (SU) Landfill

Blade Capacity

21.2 m³

Sustainability

expand / collapse icon

Recyclability

98%

Air Conditioning System

expand / collapse icon

Air Conditioning

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 2.5 kg of refrigerant which has a CO2 equivalent of 3.575 metric tonnes.

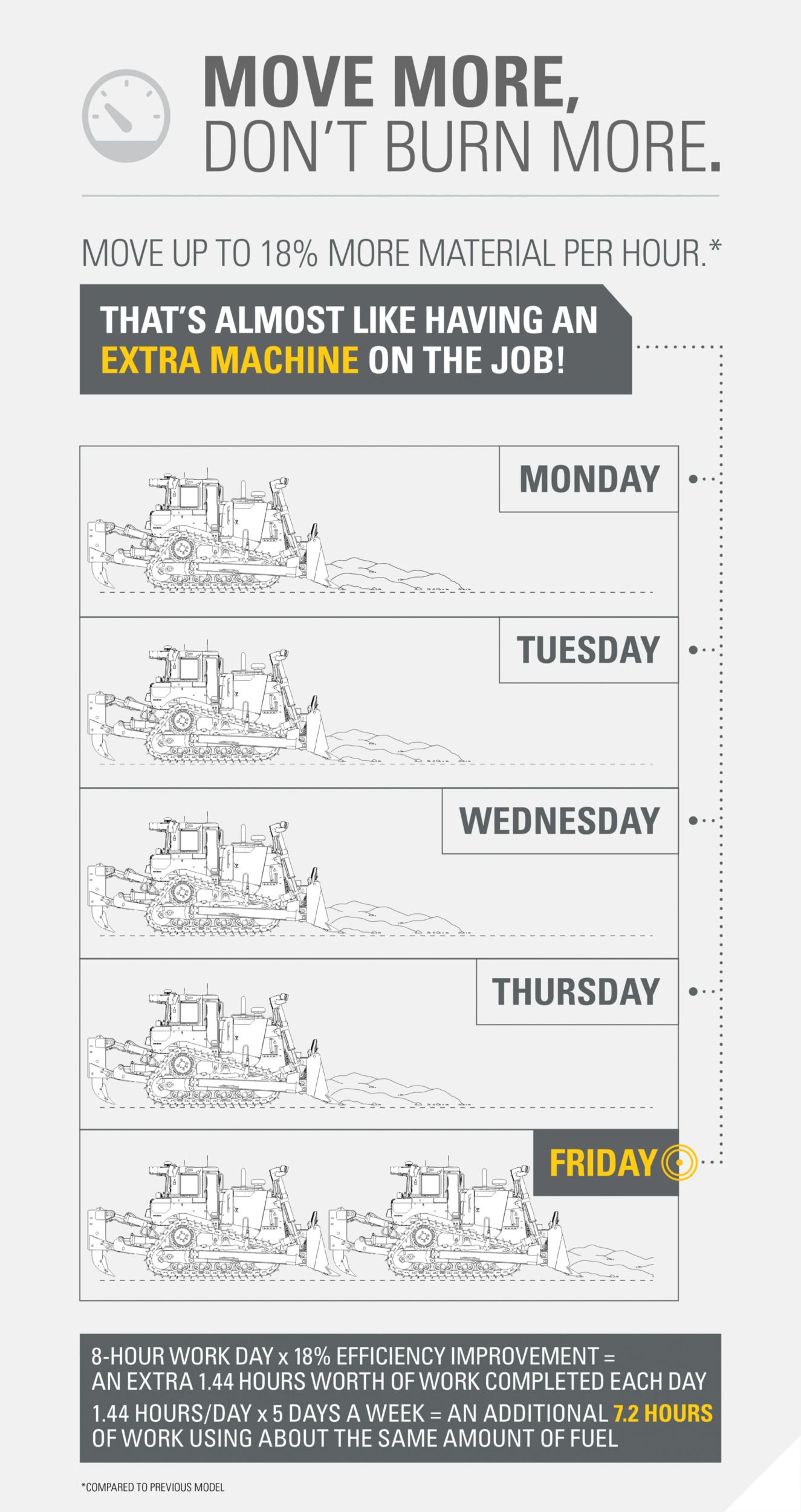

MOVE MORE WITH LESS FUEL

Move up to 18% more material per hour without burning more fuel in most applications.

Save up to 11% fuel in lighter applications.

Fully automatic 4-speed powershift transmission optimizes the dozer for maximum productivity and efficiency.

19% larger standard Semi-Universal (SU) blade moves more material per pass.

Transmission puts up to 13% more drawbar power to the ground.

10% increase in steering torque, fully automatic transmission and differential steering combine to provide best-in-class steering performance under load.

Optional FirstCut™ cutting edges increase blade payload by up to 35% compared to standard cutting edges.

Comparisons to previous model D8T Build 20 (SN Prefix FMC).

EASY TO OPERATE

Fully automatic 4-speed transmission – just select desired ground speed and the tractor will automatically manage settings for maximum efficiency and power based on load.

No need to upshift/downshift – saves effort for experienced operators and helps newer operators maximize productivity more quickly.

Added gear between first and second ensures seamless lock-up clutch engagement for exceptionally smooth shifting.

All speed and turning input is packaged in a single hand control for easy operation – thumb wheel puts easy on-the-fly ground speed changes at your fingertips.

Automatic Ripper Control and new rip-to-depth feature help reduce operator fatigue and machine wear and tear.

Engine Idle Shutdown Timer shuts the machine down after a pre-set idling period to save fuel and reduce unnecessary idling time.

Emissions reduction technology is designed to work automatically in the background while you work.

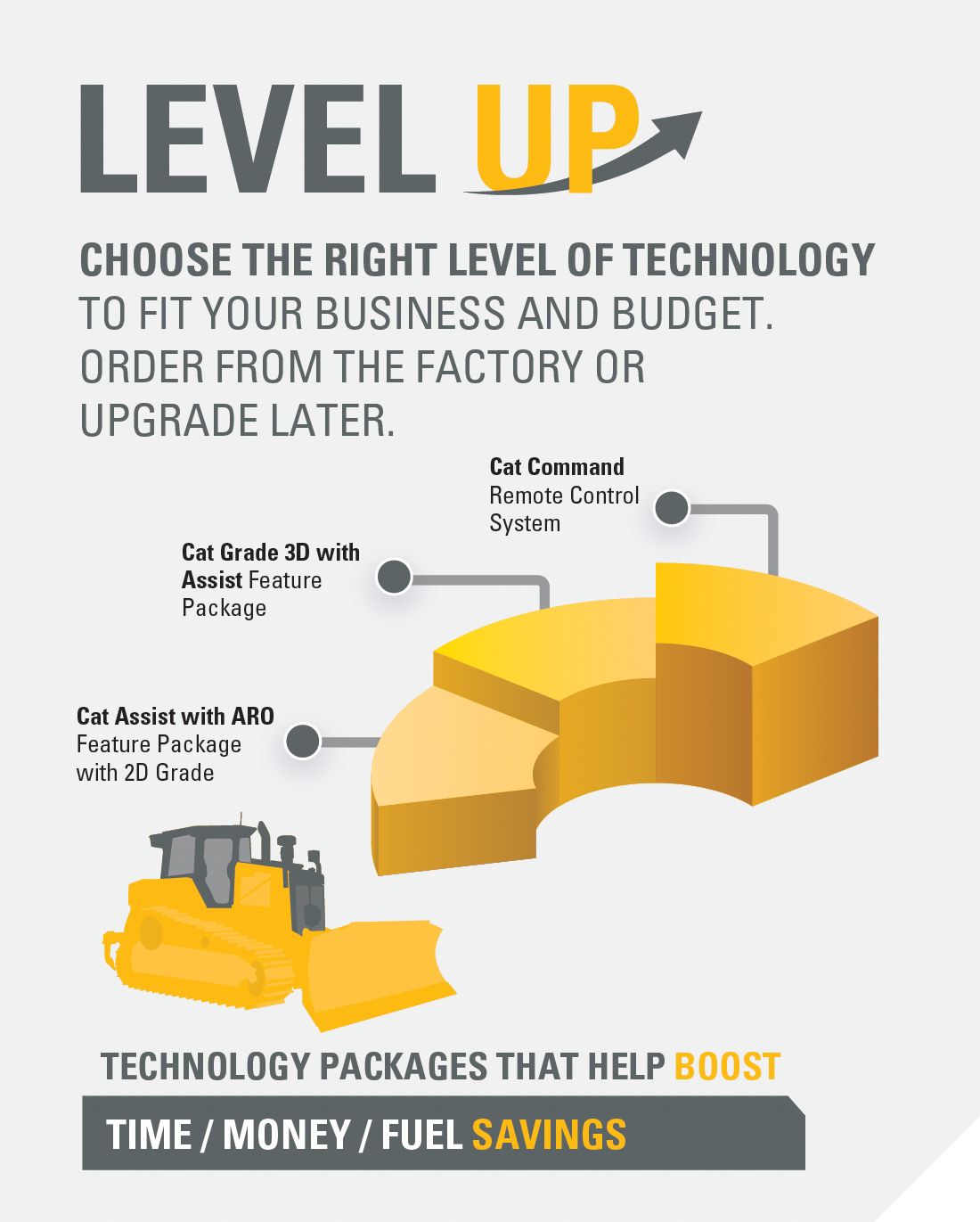

TECHNOLOGY THAT GETS WORK DONE

Hit target grade faster and more accurately with Cat Grade technologies. Finish jobs in fewer passes, and with less operator effort, saving you time and helping you increase profit.

Cat Grade with Slope Assist™ automatically maintains pre-established blade position without a GPS signal. (Single Tilt machines only).

Cat Grade with 3D option is factory-integrated grade control that helps you improve grading efficiency, accuracy and productivity. Automates blade movements in both fine grading and production dozing applications, reducing operator inputs by as much as 80%. Antennas on top of the cab eliminate blade masts and cables. Reduces need for grade checkers and staking, enhances safety and reduces labor costs.

Standard Slope Indicate displays machine cross-slope and fore/aft orientation right on the main display.

Gain even more productivity and reduce operator inputs with Auto Blade Assist, AutoCarry™ and Automatic Ripper Control.

Factory ARO Option provides optimal mounting locations, brackets, and hardware to simplify installation of an aftermarket grade control system.

All Cat Grade systems are compatible with radios and base stations from Trimble, Topcon, and Leica.

Already invested in a grade infrastructure? You can install grade systems from Trimble, Topcon, and Leica onto the machine.

Product Link™ collects machine data that can be viewed online through web and mobile applications.

Access information anytime, anywhere with VisionLink® – and use it to make informed decisions that boost productivity, lower costs, simplify maintenance, and improve safety and security on your job site.

LOWER MAINTENANCE COSTS

High quality cartridge fuel filters are purpose-built to help keep your fuel system clean and extend injector life.

High debris engine filter (optional) has a pleated design for less plugging – especially ideal for waste, wood chip, other fine debris applications.

Exclusive Cat hydraulic and power train oil filters offer extended service intervals to save you time and money.

Reduce cost, add versatility with rear implement valves that accommodate either a ripper or hydraulic winch with no changes and no trade-off in performance.

Programmable, automatic reversing fan is now standard for greater machine value at no added cost.

Larger one-piece oil pan doubles engine oil service interval to 500 hours saving you time and parts cost.

Features like grouped service points, ground level service center and modular transmission help make your daily maintenance and service tasks more convenient.

Remote Flash allows for select software updates to be made remotely via Product Link on eligible machine models, saving you time and service call expense.

Comparisons to previous model D8T Build 20 (SN Prefix FMC).

BUILT FOR LONG TERM PRODUCTION

Robust structures provide the added durability to handle the increased weight and productivity.

Caterpillar exclusive Elevated Sprocket undercarriage gives you an added edge in machine balance, component Long Term Value and Durability and ease of service.

Heavy Duty Extended Life undercarriage, HDXL with DuraLink™, is designed to help reduce your operating costs with heavier bushings for up to 25% more wear life, especially in high abrasion conditions.

Special machine arrangements are equipped from the factory for performance and longer life in harsh applications like landfill, transfer station and stock pile applications.

Major structures and components are built to be rebuilt, reducing waste, driving down lifetime operating cost, and extending the profitability cycle over more machine life.

BUILT-IN SAFETY FEATURES

Rear vision camera and cylinder mounted mirrors are available to enhance visibility around the machine.

Powered Bottom Guard option enhances safety during clean-out.

Convenient steps, handles and guardrail help you get on and off the tractor with greater ease.

Ground level access to lighting switch.

Seat belt indicator enhances safety by reminding you to buckle up with a light/alarm.

Electronic fluid level verification at startup saves you time and reduces trips up and down from the cab inspect compartments.

Standard Operator Presence detection system allows the machine to idle when the operator is not seated, but locks out the power train and front implements to avoid unintentional movement.

WASTE HANDLING PERFORMANCE

Build or close cells, push trash or spread cover – Cat Waste Handlers are designed and built from the frame up to take on the challenges of landfill work.

Specialized guarding, striker bars and seals help protect against impact and airborne debris.

Bottom and Final Drive guarding helps prevent damage from wrapping debris.

Faster cleanout and enhanced safety with optional Powered Bottom Guards.

High debris cooling system with automatic reversing fan.

Insulated Clean Emissions Module and thermal shields provide the highest level of protection.

Specialized air handling features help deliver cleaner air to the machine and to the cab.

Landfill blades and center-hole track shoes help optimize your waste handler for the job.

Lights are mounted up and away from main debris area for protection, while still shining plenty of light on the work area.

TAKE COMMAND

Cat Command for Dozing offers remote control operation for enhanced safety and greater productivity.

Command uses line-of-sight (LOS) control with an over-the-shoulder console, or a non-line-of-sight (NLOS) option using the Cat Command Station to run the machine remotely.

SUSTAINABILITY

Optimize machine performance for greatest productivity, while helping improve fuel efficiency and reduce greenhouse gas emissions with a fully automatic 4-speed transmission with lock-up clutch.

The Cat® C15 engine meets U.S. EPA Tier 4 Final, EU Stage V, and Korea Tier 5 emission standards.

Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) ** or 100% renewable diesel, HVO (hydrogenated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

Cat® Grade with Slope Assist™ helps you avoid costly rework and wasteful fuel burn and greenhouse gas emissions by automating your blade position without a GPS signal.

Cat® Grade with 3D automates blade movements using a GPS signal helping you follow a grade design, reducing fuel burn and greenhouse gas emissions by improving efficiency and accuracy.

AutoCarry™ automates blade lift to reduce track slip for maximum efficiency on each pass to help lower fuel burn and greenhouse gas emissions.

VisionLink® displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range.

Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency by allowing your Cat dealer to virtually test the machine while working. Once a problem is identified, a technician can fix it the first time, saving time and money.

All comparisons to D8T Build 20 (SN Prefix FMC). Productivity, fuel and CO2 emissions vary by application. CO2 emissions calculations based on a reference work cycle using 2.2 U.S. gallons per hour of #2 U.S. diesel fuel. Applies IPCC2006 methodology using U.S. EPA Emissions Hub emission factors. Includes DEF (diesel exhaust fluid) related CO2. Fuel measurements are at 15°C. Estimated average fuel consumption improvements are based on tests or Product Link™ data where available. Productivity improvements are based on test data.

**Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel.

D8 Standard Equipment

Expand all

NOTE

expand / collapse icon

Standard and optional equipment may vary. Consult your Cat dealer for details.

Power Train

expand / collapse icon

C15 Diesel Engine, Electronic Unit Injection (EUI), Aftertreatment to meet U.S. EPA Tier 4 Final/Korea Stage V emission standards

24V electric start

Air-to-air aftercooler (ATAAC)

Air filter with electronic service indicator

Extended life coolant

Auto reversing suction fan

Four planet, double-reduction planetary final drives

Electric fuel priming pump

High performance single plane cooling system

Electronic parking brake

Precleaner, strata-tube dust ejector

Prescreener

Shift management: Full Auto Shift

Sound attenuated exhaust system

Automatic ether starting aid

Torque divider with lock-up clutch

Transmission control module, electronic

Transmission, electronically-controlled powershift

Turbocharger

Water separator

Operator Environment

expand / collapse icon

Access/egress lighting with shutdown timer

Adjustable armrests

Air suspension seat

Cab, ROPS/FOPS, sound suppressed

Decelerator pedal

Heater and ventilation

Interior LED courtesy lights

Rearview mirror

Provision for wire passage in/out of cab

Radio, AM/FM, Bluetooth

ROPS mounted air conditioner

Seat belt, retractable

Steering control, direction and speed control thumb switches with recall button

Touch screen operator interface: Electronic monitoring system, Diagnostic service information, Operator preferences

Wipers, intermittent

Cat Technology

expand / collapse icon

Grade control ready

Compatibility with radios and base stations from Trimble, Topcon, and Leica

Capability to install 3D grade systems from Trimble, Topcon, and Leica

Power Train, Engine, Brakes

expand / collapse icon

Brakes, Basic or Extreme Service

Engine precleaner, basic or with screen

Bottom Guards

expand / collapse icon

Standard

Electrical

expand / collapse icon

Back-up alarm

Converter, 24V to 12V

Diagnostic connector

Ground level service center with hour meter

Horn, forward warning

Final Drives

expand / collapse icon

Final drives: LGP or Guarded

Final drives: Standard, Guarded or Arctic

Hydraulics

expand / collapse icon

Dozer tilt and fan hydraulics: Single Tilt or Dual Tilt

Electronically enabled quick drop valve

Hydraulics, electronically controlled, load-sensing dozer lift and tilt

Hydraulics, electronically controlled, load-sensing rear hydraulics, ripper or winch ready

Hydraulics, independent steering and work tool pumps

Other Standard Equipment

expand / collapse icon

Engine compartment service light

Equalizer bar, pinned

Front pull device

Hinged bottom guards

HVAC box, corrosive resistant

Product Link

S-O-S sampling ports

6-light package

Electronically controlled power differential steering

Vandalism protection for fluid compartments

Starters, Batteries, And Alternators

expand / collapse icon

Alternators: 150 Amp, Basic or Ducted

Batteries: Heavy duty or Arctic

Engine coolant heater (120V)

Starting receptacle, auxiliary

Undercarriage

expand / collapse icon

Positive Pin Retention Track (44 Section, sealed and lubricated, single grouser shoes)

610 mm (24 in) Extreme Service track

8-roller tubular track roller frame (Carrier roller ready)

Gauge arrangements: Standard or LGP

Rollers and idlers, lifetime lubricated

Sprocket rim segments, replaceable

Suspension-type undercarriage

Track adjusters, hydraulic

Track guide

Two-piece master links

D8 Optional Equipment

Expand all

NOTE

expand / collapse icon

Standard and optional equipment may vary. Consult your Cat dealer for details.

Power Train, Engine, Brakes

expand / collapse icon

C15 Diesel Engine, Electronic Unit Injection (EUI), Aftertreatment to meet EU Stage V emission standards

Engine, thermal shield

Oil change system, high speed

Radiator, 6.35 fins per inch, debris

Operator Environment

expand / collapse icon

Cab glass: Single pane, Enhanced Dual Pane or 40 psi

Cab platform: Standard, Quick Opening or 5th Percentile

Cab seat: Cloth, heated

Cab seat: Heated and ventilated

Visibility arrangements: Basic or Single camera

Cat Technology

expand / collapse icon

Attachment Ready Option (ARO), single tilt or dual tilt

AutoCarry/AutoRip, single tilt or dual tilt

Cat Grade with 3D

Command for Dozing Ready

Machine control, basic, single tilt or dual tilt

Product Link: Cellular or Dual mode

Bulldozers

expand / collapse icon

8A

8SU LGP

8SU/U: basic, guarded or dual tilt guarded

8U LGP: single tilt guarded or dual tilt guarded

Blades

expand / collapse icon

Angle Blade

LGP Angle

LGP SU

LGP SU Landfill

Semi-Universal (SU)

SU Landfill with Wear Plate

SU with Performance Cutting Edges

SU with Push Plate

SU with Rock Guard, Performance Cutting Edges

SU with Rock Guard, Wear Plate

Universal

Universal Landfill

Universal with Rock Guard, Wear Plate

FirstCut cutting edges (SU blades)

Undercarriage

expand / collapse icon

Positive Pin Retention (PPR) Undercarriage: Suspended, Guarded or Arctic

610 mm (24 in) Moderate Service PPR Track

610 mm (24 in) Super Extreme Service PPR Track

610 mm (24 in) Extreme Service PPR Track, trapezoidal

660 mm (26 in) Moderate Service PPR Track

660 mm (26 in) Extreme Service PPR Track

660 mm (24 in) Extreme Service PPR Track, trapezoidal

660 mm (24 in) Super Extreme Service PPR Track, trapezoidal

711 mm (28 in) Moderate Service PPR Track

711 mm (28 in) Extreme Service PPR Track

711 mm (28 in) Moderate Service PPR Track, trapezoidal

711 mm (28 in) Extreme Service PPR Track, trapezoidal

965 mm (38 in) Moderate Service PPR Track

965 mm (38 in) Extreme Service PPR Track

965 mm (38 in) Extreme Service PPR Track, trapezoidal

Heavy duty, extended life undercarriage track (44 Section, sealed and lubricated, single grouser shoes)

Heavy duty, extended life undercarriage: Suspended, Guarded or Arctic

610 mm (24 in) Moderate Service HDXL Track

610 mm (24 in) Extreme Service HDXL Track

610 mm (24 in) Super Extreme Service HDXL Track

660 mm (26 in) Extreme Service HDXL Track

660 mm (26 in) Extreme Service HDXL Track, trapezoidal

711 mm (28 in) Extreme Service HDXL Track

965 mm (38 in) Extreme Service HDXL Track

965 mm (38 in) Extreme Service HDXL Track, trapezoidal

Carrier rollers: Suspended, Suspended Arctic or No carrier rollers

Bottom Guards

expand / collapse icon

Bottom guards with front counterweight

Heavy duty, sealed

Powered

Wood chip

Electrical

expand / collapse icon

Light, warning strobe

Lighting groups: Basic, Premium or Sweeps

Mount, light, warning strobe

Guards

expand / collapse icon

Fan debris guard

Fast fuel guard

Fuel tank guard

Grill debris guard

Rear screen

Front striker bars

Sweeps group

Hydraulics

expand / collapse icon

Rear attachment hydraulics: Ripper, Winch or None

Other Attachments

expand / collapse icon

Black paint, blade

Additional counterweight

Ecology drains

Grab handles, push arm

PA140VS winch

W12 E PTO winch

Window shades

Rear Attachments

expand / collapse icon

Rear counterweight

Rigid drawbar

Multi-shank ripper

Multi-shank ripper with striker bar

No rear attachment

PA140VS winch, variable speed

Rear striker bar

Single shank ripper with pin puller

Single shank ripper with puller and striker bar

Single shank ripper with striker bar

Ripper Shank Teeth

expand / collapse icon

Multi-shank

Single shank

Single shank, deep ripping