The Cat® SE50 VT screed utilizes tamper bars and rear-mounted extenders to deliver smooth material flow and increased mat density. Stability, easy set-up, and a versatile paving range make it the perfect match for air-ports, interstates, highways, and many other mid-sized paving applications.

Standard Weight

3295 kg

Standard Paving Range

2.55 – 5.0 m (8′ 4″ – 16′ 4″)

Maximum Paving Range

8 m

Product specifications for SE50 VT Tamper Bar Screed Screeds

The Cat® SE50 VT screed utilizes tamper bars and rear-mounted extenders to deliver smooth material flow and increased mat density. Stability, easy set-up, and a versatile paving range make it the perfect match for air-ports, interstates, highways, and many other mid-sized paving applications.

Weights

expand / collapse icon

Standard Weight

3295 kg

Operating Specifications

expand / collapse icon

Standard Paving Range

2.55 – 5.0 m (8′ 4″ – 16′ 4″)

Maximum Paving Range

8 m

Tamper Speed Range

700 to 1800 rpm

Vibrator Speed Range

0 to 3000 rpm

Maximum Paving Depth

305 m

Crown Range

-2% to +5%

Extender Height Range

-20 mm to +50 mm

Heating Time – Maximum Width

25 minutes

Heating Time – Standard Width

15 minutes

Dimensions

expand / collapse icon

Transport Width – Endgates Folded

2.55 m

Transport Length – Tractor and Screed

6666 mm

Screed Plate Width – Front to Back

324 mm

Length – Front to Back, Endgates Attached

2345 mm

Length – Front to Back, Endgates Removed

1731 mm

Application Versatility

Common applications include urban and rural roads, streets, airports, highways, and interstates

The standard paving range of 2.55 m – 5 m (8′ 4″ – 16′ 4″) provides excellent performance when changing paving widths for both urban and highway paving applications

Simple, bolt-on extensions offer a maximum paving width of 8 m (26′ 3″)

Simple Operation

Operating displays can be tailored to specific language requirements with multiple options available

Exclusive 2-speed, proportional extender control provides smooth adjustment when transitioning paving widths

Screed operating consoles are equipped with ratio adjustment for the augers and conveyors, providing the ability to modify material flow

Optional power controls for extension height enables operators to quickly manage mat quality

Trailing edge screed plate adjusters help maintain an even plane across the width of the screed in order to enhance paving quality and extend screed plate life

Smooth Material Flow

Enhanced tamper-bar and deflector plate profiles provide smooth flow to the screed plates

Screed plate depths of 324 mm (12.75″) on both the main and extenders provide stability and good mat textures

The heated end gate option helps prevent material from sticking for better edge profiles and joint matching capability

Pave Start Assistant

Pave Start Assistant saves set-up profiles for repeatable use on future job sites, simply activate the profile for quick, single person setup

Set-up preferences include: tamper speed, tow-point height, screed heat temperature, paving speed, paving width, paving depth, crown, extender height (power option), screed assist, and screed locking features

Setup features are located in the left screed display and can also be viewed through right screed display and tractor displays

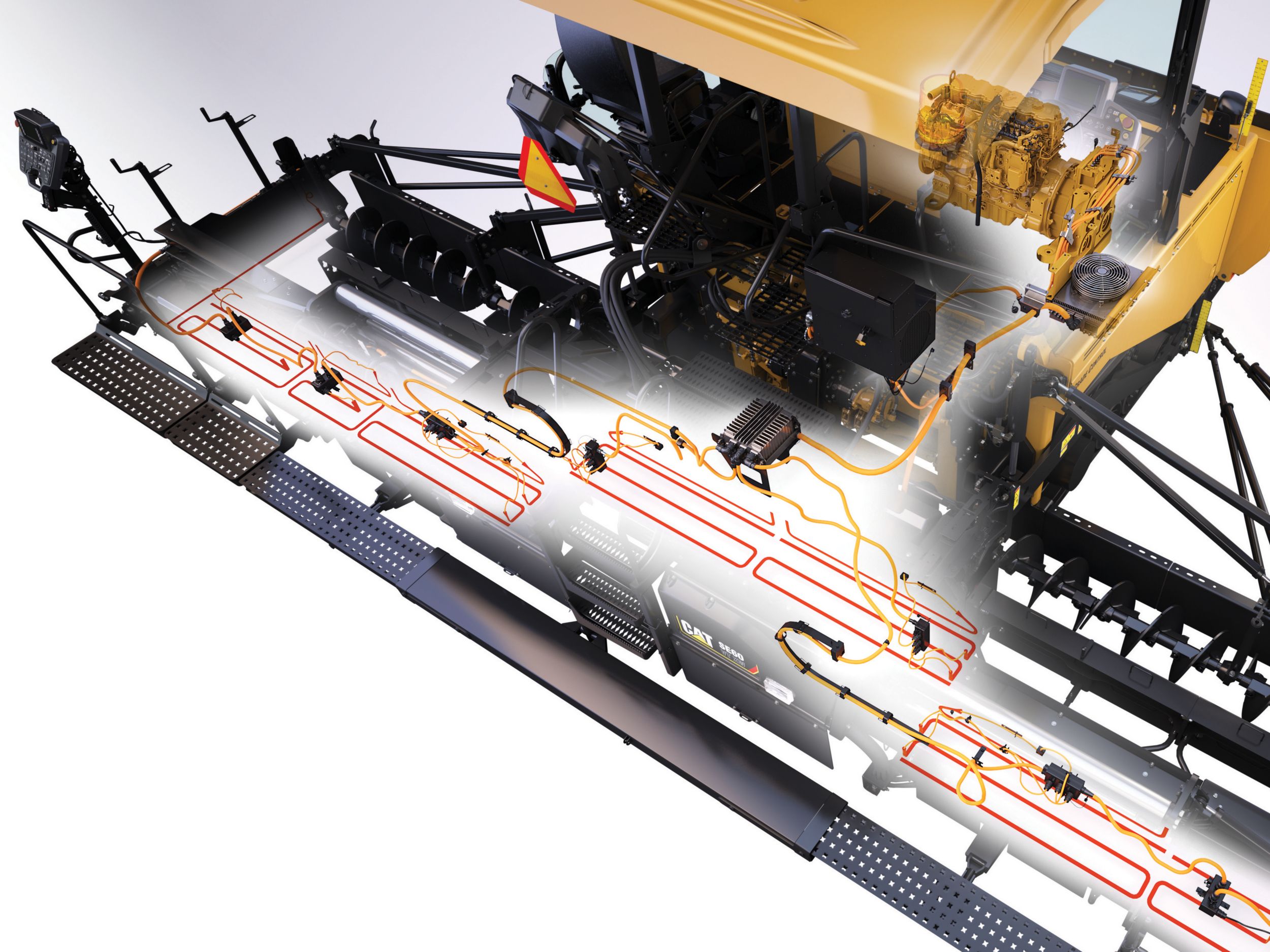

Quick Heat, Even Distribution

Tractor integrated generator delivers fast, 15-minute screed plate heating for quick starts

Electric heating system with zone monitoring helps ensure even heat distribution and smooth asphalt textures while also allowing heating to continue in the event of a temperature sensor failure

Pendent Control Option

Manual overrides and pause function capability for each auger and each conveyor are available to match changes in material flow requirements

Optional power height functions assist with profile

Automatic Grade Control activation provides flexibility when working on the outer edge of the screed

Grade Control Option

Factory-integrated leveling system that helps remove irregularities from the surface and control mat thickness for increased production, lower operating costs, and higher profitability

User-friendly system with text-based displays, split screen-mode, and on-the-go sensor selection

Precise control driven by 10-point auto-calibration, true averaging with 5 transducers in each sonic sensor, and cross-coupling feature that maintains slope requirements more consistently when changing elevation

Service Repair Kits

Paver and screed service and repair kits include the parts necessary to complete specific repairs

Cat genuine parts are manufactured to precise specifications and designed for optimal performance and maximum uptime

Repair kits are identified by a single part number to make ordering easy

Select kits are available to be packaged as a kit by the dealer for over the counter purchases or through the dealer service shop

SE50 VT Tamper Bar Screed Standard Equipment

Expand all

Power Controls

expand / collapse icon

Crown

Service repair kits

Horn_warning

Endgate_manual

Material Delivery

expand / collapse icon

Thickness screws

SE50 VT Tamper Bar Screed Optional Equipment

Expand all

Operating Environment

expand / collapse icon

Pave Start Assistant

Pendent control

Umbrella

Visor_LCD display

Technology

expand / collapse icon

Cat Grade Control

Safety

expand / collapse icon

Lights_roading

Material Delivery

expand / collapse icon

Drop arm spacer

End gate_power

Extension Packages

Folding Endgate

Heated Endgate

Cutoff Shoe

Shoe_edge

Shoe_safety edge

Shoe_wide