Small size CVD coating machine for the production of Parylene thin films

CX-30 Parylene coater is a low temperature CVD coating machine with 30L reactor volume to produce Parylene thin films. It is fully automated and incorporates surface activation processes.

The CX-30 can be integrated into production lines for electronic or medical devices or semiconductors. The machine can easily be coupled to clean rooms.

The Parylene CVD coater is also available in larger models (CX-300 and CX-600).

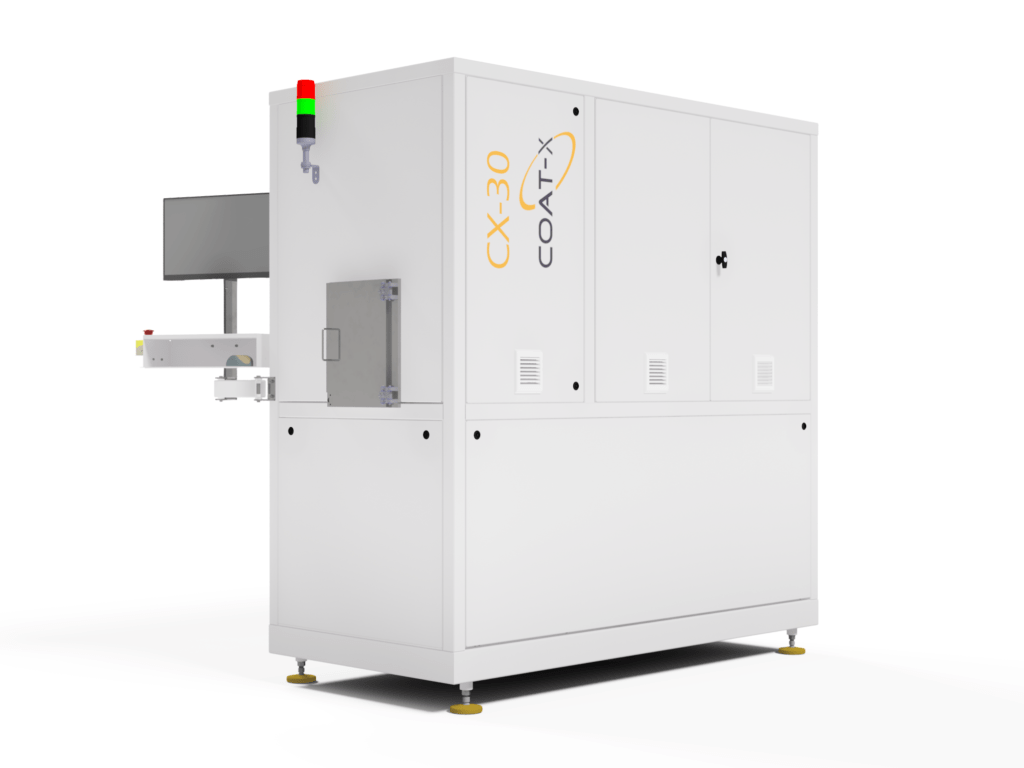

Small parylene coater CX-30 by COAT-X for parylene thin films

Small parylene coater CX-30 by COAT-X for parylene thin films

CX-30 was designed by COAT-X for the production of high quality parylene conformal coatings. It is the result of more than 10 years of intense research and development. CX-30 produces high quality, flawless parylene conformal coatings from 100 nm to 40 µm with very precise deposition rate control.

Parylene thin films produced with CX-30 are excellent moisture barrier coatings and dielectric insulators with high breakdown voltage, low coefficient of friction, excellent biocompatibility and chemical stability.

MAIN CHARACTERISTICS

CX-30 is a low temperature CVD coating machine specifically designed for the deposition of thin layers of Parylene, it integrates:

Evaporator oven

Pyrolysis furnace with quartz tube

Front loading deposition chamber

Deposition turntable

Injection of adhesion promoter

Cold traps

Pumping units

Control unit

Human Machine Interface Software

PC and screen on adjustable arm

DIMENSIONS

The CX-30 is a compact Parylene machine, it fits easily into a production line, its size is:

Length 1.9m

Width 0.9m

Height 2.0m

Diameter of working area 200 mm, height 400 mm

AVAILABLE OPTIONS

The following options are available for the CX-30:

Activation of oxygen plasma

PE-CVD module for the deposition of multilayer composite thin films of Parylene and Ceramic.

Automated Nitrogen Refill

Thermo-regulated reactor chamber

Clean room interface

Specific coating device

Consumables for parylene deposition can be purchased at COAT-X, such as parylene-C, parylene-VT4 and parylene-AF4 dimer granules or ceramic precursors.

APPLICATIONS

The CX-30 produces thin hermetic parylene films to protect sensitive products against moisture such as:

Printed circuit boards (PCB and PCBA)

Sensors and actuators

MEMS

LEDs

Medical equipement

Additionally, the thin parylene film provides a biocompatible surface for implantable devices, such as:

Cardiovascular stents

Heart monitoring systems

Intraocular pressure control

Intragastric balloon

SERVICES

COAT-X takes care of:

Development of an optimal deposition recipe

Design and production of fixtures

Supply of consumables and spare parts

FAT and SAT qualifications

Process validation support

Repair and service on demand

Worldwide delivery